Mejora del proceso de fresado de dientes de engranajes: un estudio de caso en una pequeña empresa

DOI:

https://doi.org/10.47456/bjpe.v9i2.39929Palabras clave:

Métodos de mecanizado, centro de mecanizado vertical, herramientas de corteResumen

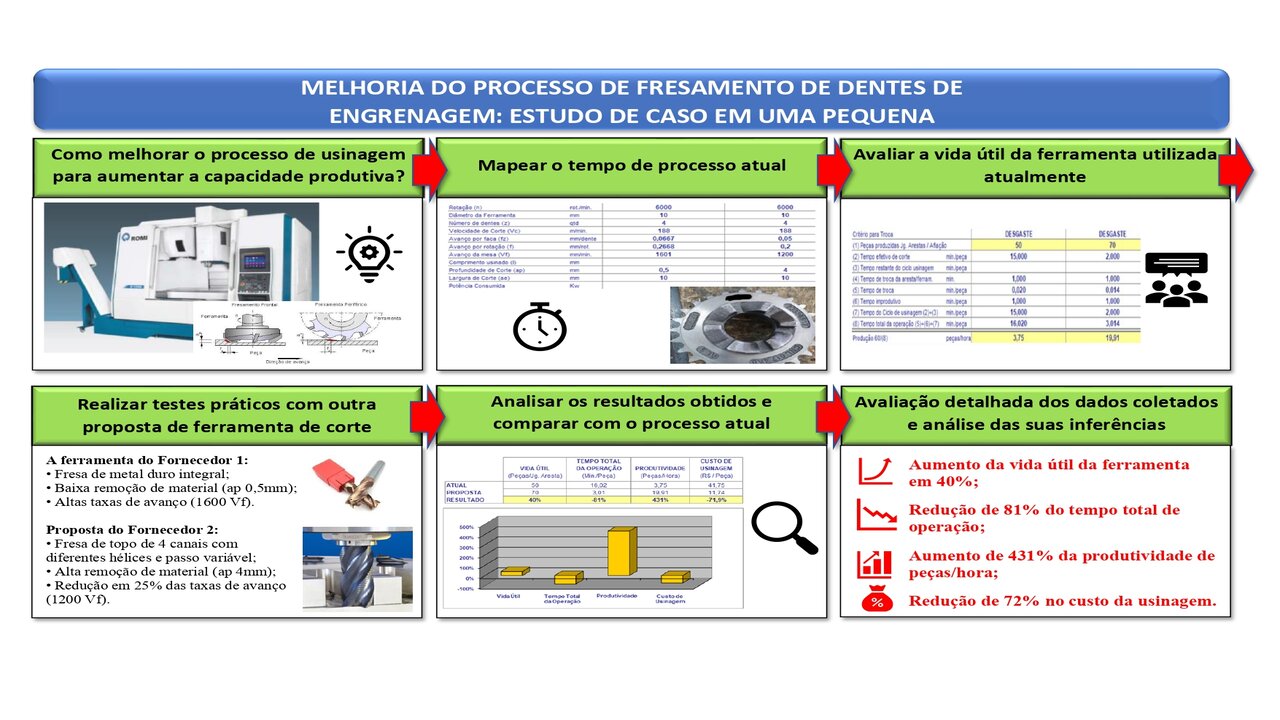

La mejora continua de la productividad es un problema en las empresas. La gestión del tiempo en el proceso cobra relevancia y valor de análisis, especialmente el tiempo de mecanizado, que es un punto crítico a analizar. Debido al método utilizado para mecanizar las piezas, generalmente con tolerancias dimensionales críticas, es necesario realizarlas con precisión para obtener un buen resultado. Como el tiempo limita la productividad, constantemente se toman medidas para reducir y optimizar los procesos. El objetivo de este trabajo fue desarrollar un estudio que demostrara el aumento de la productividad a través de la reducción de los tiempos de mecanizado al utilizar herramientas de corte con alto rendimiento en velocidad de corte y tasa de arranque de viruta. Se analizaron los pasos dados en el sector del mecanizado en una pequeña empresa, en un centro de mecanizado vertical. A través de un estudio de caso cualitativo y cuantitativo, se analizó el antes y el después de la industria y los impactos, destacando acciones a través de los datos recopilados. El resultado obtenido al final de este análisis fue que a través de acciones sencillas se incidió directamente de manera positiva en la productividad y eficiencia del área.

Descargas

Citas

Abdelrazek, A. H., Choudhury, I. A., Nukman, Y., & Kazi, S. N. (2020). Metal cutting lubricants and cutting tools: A review on the performance improvement and sustainability assessment. The International Journal of Advanced Manufacturing Technology, 106(9), 4221-4245. https://doi.org/10.1007/s00170-019-04890-w DOI: https://doi.org/10.1007/s00170-019-04890-w

Barnes, R. M. (1968). Motion and Time Study: Design and Measurement of Work. Wiley.

Costa, A. M., Mattos, A. K. de M., Rodrigues, N. M., & Barboza, D. V. (2019). Aplicando a Modelagem de Processos de Negócio em uma Retificadora de Motores em Cabo Frio-RJ. Brazilian Journal of Production Engineering, 5(2), 130-142.

Diniz, A. E., Marcondes, F. C., & Coppini, N. L. (2014). Tecnologia da Usinagem dos Materiais. 8.

El-Hofy, H. (2018). Conventional and Nonconventional Processes, Third Edition (3oed). CRC Press. https://doi.org/10.1201/9780429443329 DOI: https://doi.org/10.1201/9780429443329

Ferraresi, D. (2018). Fundamentos da Usinagem dos Metais. Editora Blucher.

Gil, A. C. (2002). Como elaborar projetos de pesquisa (Vol. 4). Atlas São Paulo.

ISCAR. (2022). https://www.iscar.com/newarticles.aspx/lang/bz/newarticleid/4205

Klocke, F. (2011). Manufacturing Processes 1: Cutting. Springer Science & Business Media. DOI: https://doi.org/10.1007/978-3-642-11979-8

Knechtel, M. do R. (2014). Metodologia da pesquisa em educação: Uma abordagem teórico-prática dialogada. Curitiba: Intersaberes.

Lafin, P. (2018). Estudo comparativo de ferramentas do tipo alisadora e convencional no torneamento do aço AISI 1045. https://repositorio.ifsc.edu.br/handle/123456789/250

Machado, Á. R., Abrão, A. M., Coelho, R. T., Silva, M. B. da, & Ruffino, R. T. (2009). Teoria da usinagem dos materiais. https://repositorio.usp.br/item/002126508

Schnorrenberger, J. G. A., & Nunes, F. D. L. (2019). Eficiência de Equipamentos: Aplicação de uma Ferramenta para Medir o Desempenho de Equipamentos em uma Empresa Metalmecânica de Pequeno Porte no Sul do Brasil. Brazilian Journal of Production Engineering, 5(6), 86-107.

Silva, M. M., da. (2019). Melhoria do processo de usinagem em torno CNC com o auxílio do sistema Lean Manufacturing. https://bibliodigital.unijui.edu.br:8443/xmlui/handle/123456789/6040

Stoeterau, R. L. (2004). Introdução ao projeto de máquina-ferramentas modernas. Universidade Federal de Santa Catarina, 28.

Toenshoff, H. K., & Denkena, B. (2013). Basics of Cutting and Abrasive Processes. Springer Science & Business Media. DOI: https://doi.org/10.1007/978-3-642-33257-9

Yin, R. K. (2015). Planejamento e métodos (5o ed). Bookman Editora.

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2023 Brazilian Journal of Production Engineering

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.