Application of reliability-centered maintenance in a steel mill

DOI:

https://doi.org/10.47456/bjpe.v9i3.41098Keywords:

Reliability-Centered Maintenance, Blast Furnace, Steel MillAbstract

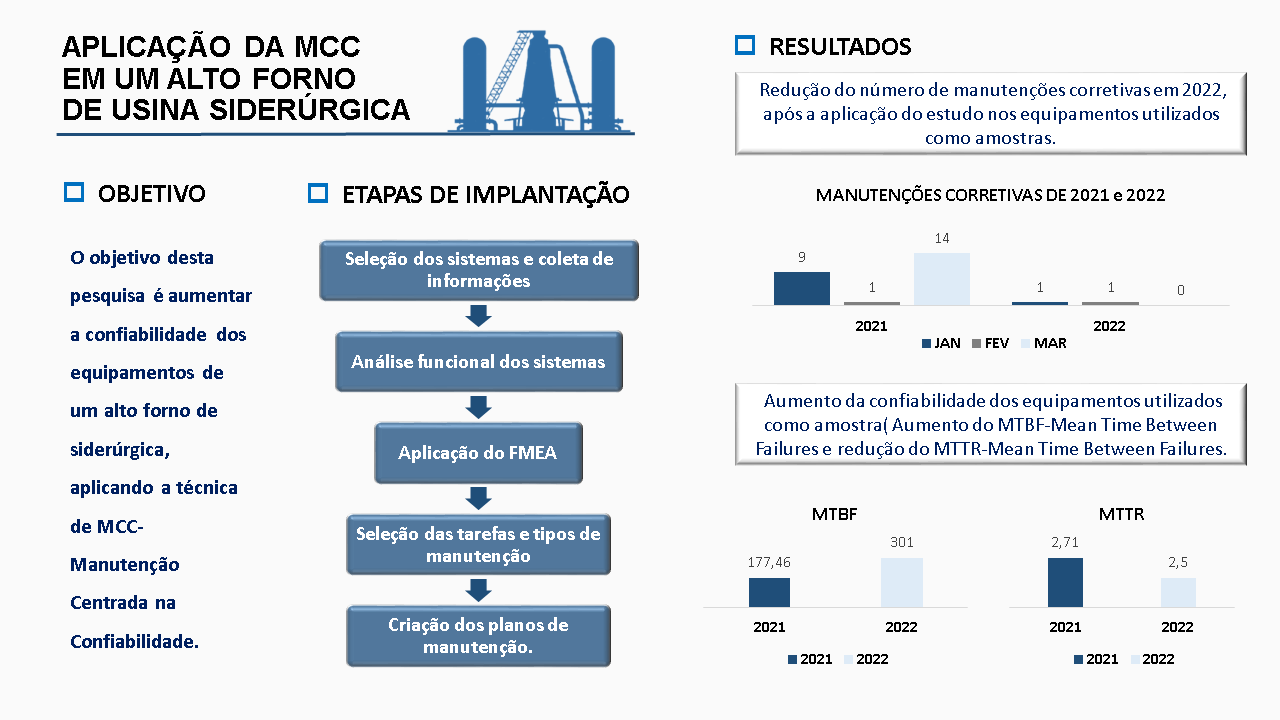

The technological development has been causing several changes in the industrial process and has led to the need for maintenance improvement due to the importance of operational availability for companies' results. In this study, the goal was to apply Reliability Centered Maintenance (RCM) to the highly critical equipment of a steel mill's blast furnace and to present the benefits obtained after implementation. As an initial sample, the motor starters in the engine room were used, given the high number of corrective maintenance actions and long downtimes during failure occurrences. For the method's applicability, the five implementation stages were followed, and finally, a comparison was made between the maintenance plans before and after RCMRCM implementation, presenting the gains achieved through a reduction in the number of corrective maintenance actions in a specific analysis period. By applying RCMRCM to the equipment with criticality A, there was a decrease in corrective maintenance actions in 2022 compared to 2021, as well as an increase in MTBF (Mean Time Between Failures) and a reduction in MTTR (Mean Time to Repair) for the studied equipment.

Downloads

References

Afefy, I. (2010). Reliability-Centered Maintenance Methodology and Application: A Case Study. Engineering, 02. https://doi.org/10.4236/eng.2010.211109 DOI: https://doi.org/10.4236/eng.2010.211109

Associação Brasileira de Normas Técnicas (ABNT). (1994). Confiabilidade e Mantenabilidade – Terminologia, NBR 5462. Rio de Janeiro.

Deshpande, V. S. & Modak, J. P. (2002). Application of RCM to a medium scale industry. Reliability Engineering & System Safety, 77(1), 31-43. https://doi.org/10.1016/S0951-8320(02)00011-X DOI: https://doi.org/10.1016/S0951-8320(02)00011-X

Fazle, R. M. (2018). Assessment of fuzzy failure mode and effect analysis (FMEA) for reach stacker crane (RST): A case study. International Journal of Research in Industrial Engineering, 7(3), 336-348. https://doi.org/10.22105/riej.2018.140970.1050

Fernández, J., & Márquez, A. (2012). Maintenance Management in Network Utilities: Framework and Practical Implementation. London: Springer. https://www.researchgate.net/publication/314041265_Maintenance_Management_in_Network_Utilities

Fogliatto, F. S. & Ribeiro, J. L. (2011). Confiabilidade e manutenção industrial [recurso eletrônico]. Rio de Janeiro: Elsevier ABEPRO.

Geerdes, M., Vliet C., Toxopeus H., & Medeiros F. (2004). Práticas modernas para operação de alto-fornos. [S. l.: s. n.]. 128p.

Kardec, A. & Nascif, J. (2009). Manutenção: Função Estratégica (3a ed.). Rio de Janeiro: Qualitymark Editora.

Kardec, A. & Nascif, J. (2012). Manutenção: Função Estratégica (4a ed.). Rio de Janeiro: Qualitymark Editora.

LaFraia, J. R. B. (2014). Manual de Confiabilidade, Mantenabilidade e Disponibilidade. Rio de Janeiro, RJ: Editora Qualitymark.

Manutenção. (2016). Manutenção em Foco. Classificação ABC de Máquinas e Equipamentos. Recuperado de

https://www.manutencaoemfoco.com.br/classificac ao-abc/

Siqueira, I. (2005). Manutenção centrada na confiabilidade: Manual de implementação. Rio de Janeiro: Qualitymark.

Smith, A. M. (1993). Reliability-Centered Maintenance. USA: McGraw-Hill, Inc.

Teles, J. (2019). Bíblia do RCM – O guia completo e definitivo da Manutenção Centrada na Confiabilidade da era de indústria 4.0. Brasília: Engeteles.

Vidal, R., Guay, M., Tremblay, P., Dion, J., & Gagné, M. (2019). A study of the performance of the furnace lining in an iron-making blast furnace. Journal of Iron and Steel Research, International.

Wyrebski, J. (1997). Manutenção Produtiva Total - Um modelo adaptado. Dissertação de mestrado, Universidade Federal de Santa Catarina. Recuperado de https://repositorio.ufsc.br/xmlui/handle/123456789/158161

Xavier, J. (2010). Indicadores de Manutenção. Recuperado de http://www.univasf.edu.br/~castro.silva/disciplinas/ MAN/indicadores_manutencao.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Brazilian Journal of Production Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.