Application of QFD methodology in the development of support used in racing drones made through additive manufacturing

DOI:

https://doi.org/10.47456/bjpe.v10i1.42915Keywords:

Fused Deposition Modeling, Quality Function Deployment, Additive Manufacturing, Product DesignAbstract

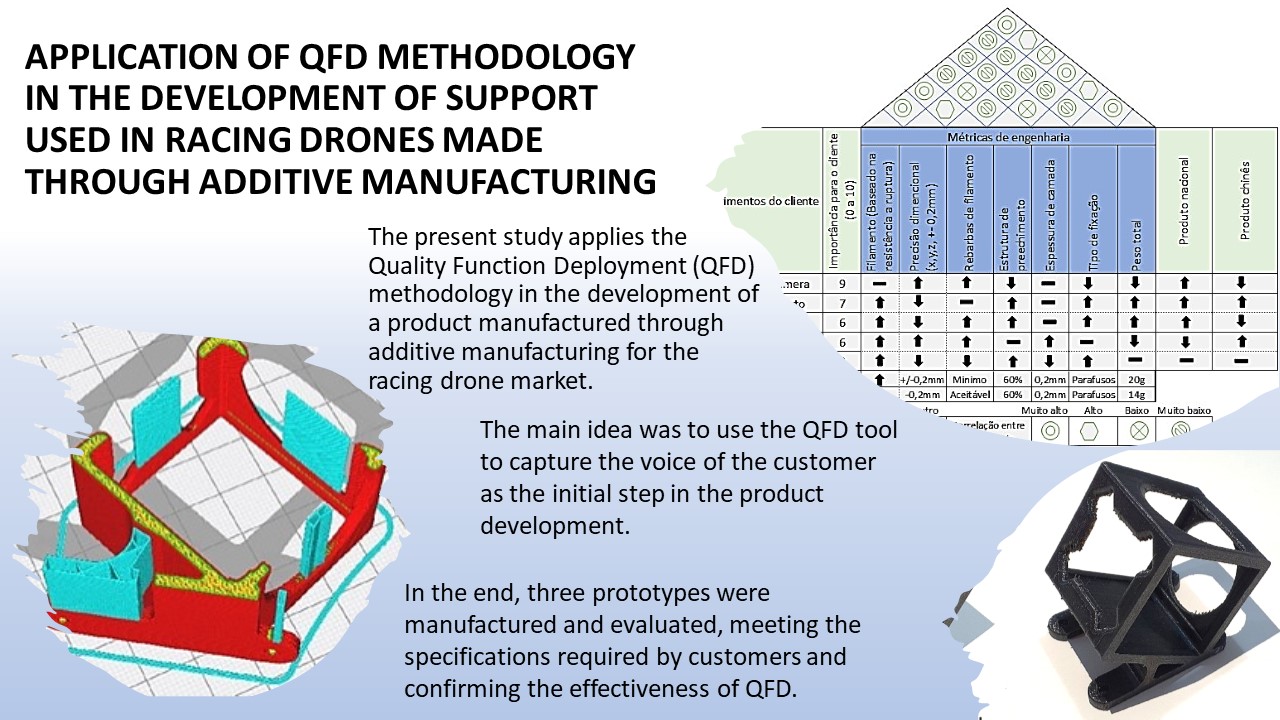

The drone industry has been growing, especially in the racing drone niche, often built using modular parts following the "do it yourself" (DIY) concept. This article explores the use of a methodology for defining customer criteria, Quality Function Deployment (QFD), presenting its application in the development of a product manufactured by Fused Deposition Modeling (FDM) for a GoPro® camera mount on racing drones. 3D printers are widely used due to their speed and ease of use, especially in the rapid prototyping of parts. Applying QFD to build a prototype of an action camera mount for racing drones that meets customer demands, subsequently manufactured by 3D printing, and evaluating pre-established parameters. The results met the pre-established QFD parameters, especially the v03 prototype, which achieved the best results. The tool was particularly useful in defining which criteria would be studied and how they would be applied in the product development process.

Downloads

References

Akao, Y. & Mazur, G. H. (2003). The leading edge in QFD: Past, present and future. Em International Journal of Quality & Reliability Management (Vol. 20, Número 1, p. 20–35). https://doi.org/10.1108/02656710310453791 DOI: https://doi.org/10.1108/02656710310453791

Banjanin, B., Vladić, G., Pál, M., Baloš, S., Dramićanin, M., Rackov, M., & Kneţević, I. (2018). Consistency analysis of mechanical properties of elements produced by FDM additive manufacturing technology. Revista Materia, 23(4). https://doi.org/10.1590/s1517-707620180004.0584 DOI: https://doi.org/10.1590/s1517-707620180004.0584

Bastidas, G., Nery, R., & Carvalho, M. M. (2001). Uso do qfd no setor de serviços: avaliação de uma transportadora rodoviária de carga.

Bottani, E. & Rizzi, A. (2006). Strategic management of logistics service: A fuzzy QFD approach. International Journal of Production Economics, 103(2), 585-599. https://doi.org/10.1016/J.IJPE.2005.11.006 DOI: https://doi.org/10.1016/j.ijpe.2005.11.006

Cavalcante, W. S. da S., Da Silva, N. F., Teixeira, M. B., Neto, G. Z., Filho, F. R. C., Cunha, F. N., & Corrêa, F. R. (2022). Tecnologias e inovações no uso de drones na agricultura / Technologies and innovations in the use of drones in agriculture. Brazilian Journal of Development, 8(1), 7108-7117. https://doi.org/10.34117/bjdv8n1-481 DOI: https://doi.org/10.34117/bjdv8n1-481

Chao, L. P. & Ishii, K. (2004). Project quality function deployment. International Journal of Quality & Reliability Management, 21(9), 938-958. https://doi.org/10.1108/02656710410561763 DOI: https://doi.org/10.1108/02656710410561763

Cohen, L. (1995). Quality function deployment: how to make QFD work for you. Prentice Hall.

Consumer Drone Market. (2023). https://www.grandviewresearch.com/industry-analysis/consumer-drone-market

Cooper, G. R. (2000). Winning with new products: doing it right (6o ed, Vol. 64).

Dwyer, C. M., Carrillo, J. G., De la Peña, J. A. D., Santiago, C. C., MacDonald, E., Rhinehart, J., Williams, R. M., Burhop, M., Yelamanchi, B., & Cortes, P. (2023). Impact Performance of 3D Printed Spatially Varying Elastomeric Lattices. Polymers, 15(5), 1178. https://doi.org/10.3390/polym15051178 DOI: https://doi.org/10.3390/polym15051178

El-Shekeil, Y. A., Sapuan, S. M., Abdan, K., & Zainudin, E. S. (2012). Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Materials and Design, 40, 299-303. https://doi.org/10.1016/j.matdes.2012.04.003 DOI: https://doi.org/10.1016/j.matdes.2012.04.003

Ficalora, J. P. & Cohen, L. (2009). Quality Function Deployment and Six Sigma A Qfd Handbook. Prentice Hall.

Filho, E. R., Ferreira, C. V, Miguel, P. A. C., Gouvinhas, R., & Naveiro, R. (2009). Projeto do Produto (1o ed). Elsevier.

Haryńska, A., Gubanska, I., Kucinska-Lipka, J., & Janik, H. (2018). Fabrication and characterization of flexible medical-grade TPU filament for Fused Deposition Modeling 3DP technology. Polymers, 10(12). https://doi.org/10.3390/polym10121304 DOI: https://doi.org/10.3390/polym10121304

Kiill Santos, J., Paulo de Souza, J., & José Borges, W. (2019). Matrix QFD: study and application in a fashion confectionary company. Revista Gestão da Produção Operações e Sistemas, 14(1), 48-76. https://doi.org/10.15675/gepros.v14i1.2053 DOI: https://doi.org/10.15675/gepros.v14i1.2053

Lubombo, C. & Huneault, M. A. (2018). Effect of infill patterns on the mechanical performance of lightweight 3D-printed cellular PLA parts. Materials Today Communications, 17, 214-228. https://doi.org/10.1016/J.MTCOMM.2018.09.017 DOI: https://doi.org/10.1016/j.mtcomm.2018.09.017

Silva, L. & Menezes, M. (2005). Metodologia da Pesquisa e Elaboração de Dissertação (4o ed). http://www.ufsc.brCTCCentroTecnológicohttp://www.ctc.ufsc.brhttp://www.ced.ufsc.brhttp://www.cin.ufsc.br

Malhotra, N. K. (2006). Pesquisa de marketing: uma orientação aplicada (4o ed). Bookman.

Melnikova, R., Ehrmann, A., & Finsterbusch, K. (2014). 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. IOP Conference Series: Materials Science and Engineering, 62(1). https://doi.org/10.1088/1757-899X/62/1/012018 DOI: https://doi.org/10.1088/1757-899X/62/1/012018

Miguel, P. A. C., Telfser, M., Maruca, A., Gallonetti, A., Saracura, A., Martins, L., Hori, M., Ribeiro, P., Campos, R. de, Marconato, T., & Mora, V. (2003). Desdobramento da qualidade no desenvolvimento de filmes flexíveis para embalagens. Polímeros, 13(2), 87-94. https://doi.org/10.1590/S0104-14282003000200005 DOI: https://doi.org/10.1590/S0104-14282003000200005

Oakland, J. & Pereira, A. G. (2007). Gerenciamento da qualidade total TQM (1o ed). Nobel.

Pinto, J. K., & Kharbanda, O. P. (1996). How to fail in project management (without really trying). Business Horizons, 39(4), 45-53. https://doi.org/10.1016/S0007-6813(96)90051-8 DOI: https://doi.org/10.1016/S0007-6813(96)90051-8

Podroužek, J., Marcon, M., Ninčević, K., & Wan-Wendner, R. (2019). Bio-inspired 3D infill patterns for additive manufacturing and structural applications. Materials, 12(3). https://doi.org/10.3390/ma12030499 DOI: https://doi.org/10.3390/ma12030499

Simões, C. L., Viana, J. C., & Cunha, A. M. (2009). Mechanical properties of poly(ε-caprolactone) and poly(lactic acid) blends. Journal of Applied Polymer Science, 112(1), 345-352. https://doi.org/10.1002/app.29425 DOI: https://doi.org/10.1002/app.29425

Stansbury, J. W. & Idacavage, M. J. (2016). 3D printing with polymers: Challenges among expanding options and opportunities. Dental Materials, 32(1), 54-64. https://doi.org/10.1016/j.dental.2015.09.018 DOI: https://doi.org/10.1016/j.dental.2015.09.018

Su, A. & Al’Aref, S. J. (2018). History of 3D printing. Em 3D Printing Applications in Cardiovascular Medicine (p. 1-10). Elsevier. https://doi.org/10.1016/B978-0-12-803917-5.00001-8 DOI: https://doi.org/10.1016/B978-0-12-803917-5.00001-8

Tymrak, B. M., Kreiger, M., & Pearce, J. M. (2014). Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Materials & Design, 58, 242-246. https://doi.org/10.1016/J.MATDES.2014.02.038 DOI: https://doi.org/10.1016/j.matdes.2014.02.038

Unterleider, C. E. A. & Sellitto, M. A. (2012). Aplicação do qfd em etapas iniciais do desenvolvimento de um odorizador de automóveis. Revista Produção Online, 12(2), 377-401. https://doi.org/10.14488/1676-1901.v12i2.848 DOI: https://doi.org/10.14488/1676-1901.v12i2.848

Volpato, L. F., Meneghim, M. de C., Pereira, A. C., & Ambrosano, G. M. B. (2010). Planejamento da qualidade nas unidades de saúde da família, utilizando o Desdobramento da Função Qualidade (QFD). Cadernos de Saúde Pública, 26(8), 1561-1572. https://doi.org/10.1590/S0102-311X2010000800010 DOI: https://doi.org/10.1590/S0102-311X2010000800010

Wilson, E. (2010). Maximizing Designers’ Impact on Market Success through Product Definition. Design Management Journal (Former Series), 4(4), 62-68. https://doi.org/10.1111/j.1948-7169.1993.tb00374.x DOI: https://doi.org/10.1111/j.1948-7169.1993.tb00374.x

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Brazilian Journal of Production Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.