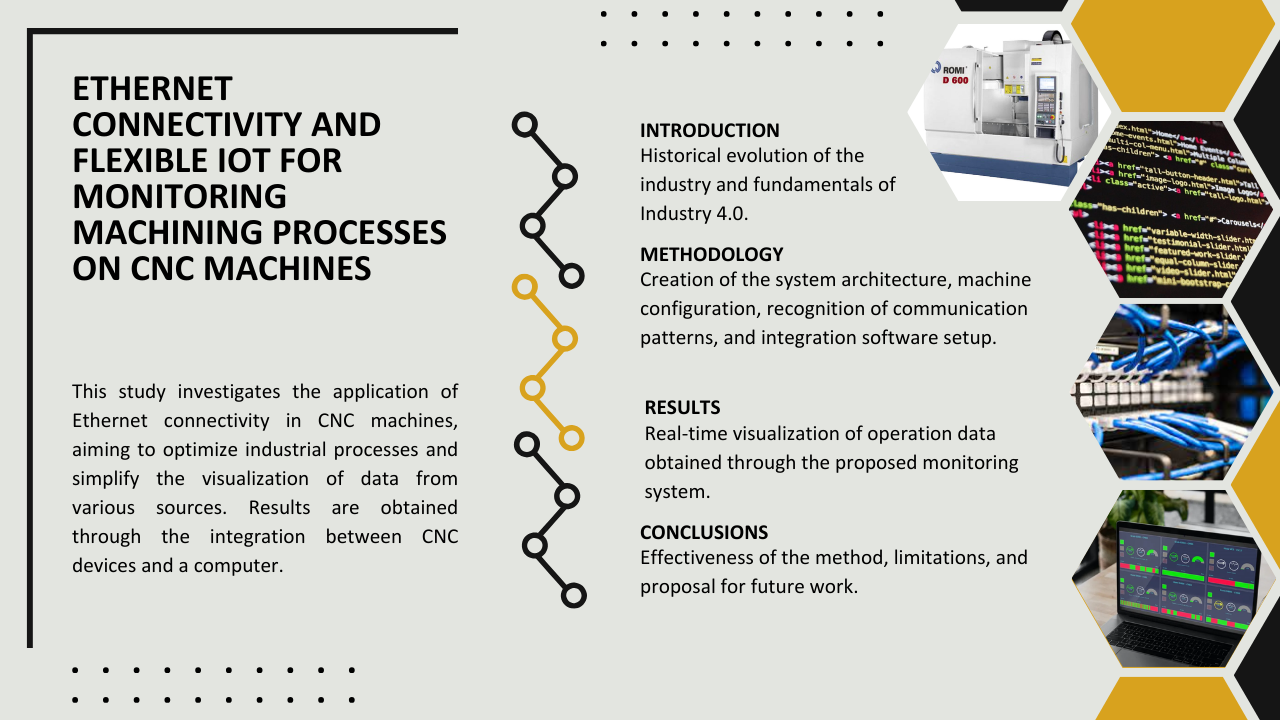

Ethernet connectivity and flexible Iot for monitoring machining processes in Cnc machines

DOI:

https://doi.org/10.47456/bjpe.v10i1.43818Keywords:

Industry 4.0, Internet of Things, Monitoring, CNC, EthernetAbstract

This study investigates the application of Ethernet connectivity in CNC machines, aiming to simplify the visualization of data from various sources. The main focus lies in designing a connection architecture that enables seamless integration between a ROMI D600 Machining Center, a ROMI GL 240 CNC lathe, and a central computer. This integrated architecture not only generated and presented real-time operational data from the machines but also provided a set of interactive dashboards. The results concretely validate the benefits offered by the implementation of Industry 4.0 technologies in manufacturing systems, demonstrating the effectiveness of the proposed approach in facilitating the ability for instant analysis of operations across multiple devices..

Downloads

References

Suh, Suk-Hwan, Kang, S. K., Chung, Dae-Hyuk, & Stroud, I. (2008). Theory and Design of CNC System. Londres, Inglaterra: Springer. DOI: https://doi.org/10.1007/978-1-84800-336-1

Nogueira, C. P. M. (2016). Rumo a Industria 4.0 (Dissertação de Mestrado). Universidade de Coimbra, Coimbra, PT19, Portugal. Recuperado de https://estudogeral.uc.pt/bitstream/10316/36992/1/Tese%20Pedro%20Coelho%20Rumo%20%C3%A0%20Industria%204.0.pdf

Barbosa, L. (2019). Estudo da adequação de uma máquina de manufatura para rede de comunicação ethernet (Monografia). Universidade Federal de Goiás, Goiânia, GO, Brasil. Recuperado de https://repositorio.bc.ufg.br/items/6288fbee-08d3-4cb7-9d3e-48842a1a858b

Indústrias Romi SA. (n.d.). Technical specifications vertical machining centers Romi D Series. São Paulo, SP. Recuperado de https://www.romi.com/wp-content/uploads/2016/02/ds_romi_d_in_aq_final_bx.pdf

Indústrias Romi SA. (n.d.). Características técnicas Centro de torneamento Romi GL 240/GL 280. São Paulo, SP. Recuperado de https://pt.scribd.com/document/407805591/ds-romi-gl-240-280-po-ap-042016-baixa-pdf

FANUC. Biblioteca FOCAS. (n.d.). Recuperado de https://www.fanuc.eu/pt/pt/cnc/development-software/focas-development-libraries

GRV Software. (n.d.). MTConnect - Entenda o que é e o que muda nas máquinas e nas fábricas. Recuperado de https://grvsoftware.com.br/mtconnect/

CNC Monitor. (n.d.). Guia de Orientações. Recuperado de https://cncmonitor.com.br/ajuda/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Brazilian Journal of Production Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.