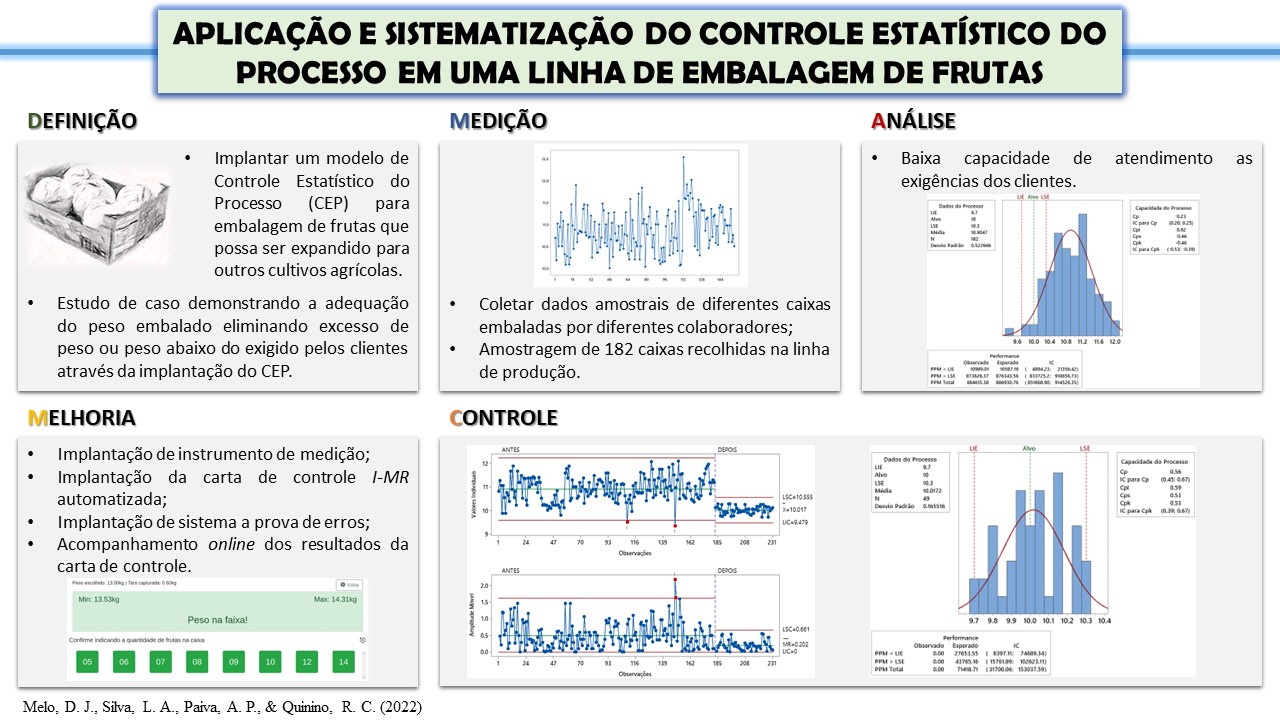

Aplicación y sistematización del control estadístico de proceso (cep) en una línea de empaque de frutas

DOI:

https://doi.org/10.47456/bjpe.v8i4.37577Palabras clave:

Agricultura, Capacidad de procesamiento, Tabla de control, ficha técnica, Industria 4.0Resumen

La agricultura es uno de los segmentos más importantes de la economía mundial, responsable de apalancar el PIB de muchos países como China, Brasil, India y Estados Unidos. Con tan gran representatividad, el desarrollo y aplicación de herramientas de mejora en este segmento cobra gran relevancia. En este sentido, este artículo tiene como objetivo presentar la aplicación del Control Estadístico de Procesos (SPC) integrado con el concepto de Industria 4.0 para reducir las pérdidas de proceso en una línea de envasado de una empresa frutícola. De las herramientas que componen el CEP, se integró a un sistema digital y en línea el análisis de capacidad y el cuadro de control I-MR para analizar la adecuación del proceso con las expectativas del cliente. Los resultados de la aplicación del sistema fueron la reducción de la pérdida de paquetes con peso fuera de los estándares de especificación, teniendo una reducción del promedio del peso del paquete en 8.10%, y desviación del promedio del proceso a la meta de solo 0.17% . El proceso también se ha vuelto más robusto, con una reducción de la desviación estándar del 68,33 %. Así, es posible concluir la eficiencia de la aplicación del CEP con un sistema digital para obtener mejores resultados en los procesos agrícolas.

Descargas

Citas

Abbas, Z., Nazir, H. Z., Akhtar, N., Abid, & M., Riaz, M. (2020). On designing an efficient control chart to monitor fraction nonconforming. Quality and Reliability Engineering International, 36(2), 547–564. https://doi.org/10.1002/qre.2590

Addeh, J., Ebrahimzadeh, A., Azarbad, M., & Ranaee, V. (2014). Statistical process control using optimized neural networks: A case study. ISA Transactions, 53(5), 1489–1499. https://doi.org/10.1016/j.isatra.2013.07.018

American Society for Quality (2000). ANSI/ISO/ASQ 9004-2000. Milwaukee: ASQ Quality Press.

Aslam M., Azam M., Khan N., & Jun C. (2015). A mixed control chart to monitor the process. International Journal of Production Research, 53(15), 4684–4693. https://doi.org/10.1080/00207543.2015.1031354

Casella, G. & Berger, R. L. (1990). Statistical Inference (2ª ed.). Florida: Duxbury Press.

Cheng, C. B. (2005). Fuzzy process control: construction of control charts with fuzzy numbers. Fuzzy sets and Sustems, 154(2), 287-303. https://doi.org/10.1016/j.fss.2005.03.002

Cooksey, R. W. (2020). Illustrating Statistical Procedures: Finding Meaning in Quantitative Data. (3ª ed). Nova Iorque: Springer.

Darestani, S. A., & Nasiri, M. (2016). Statistical process control: Fuzzy X ̅-S control chart and process capability índices in normal data environment. International Journal of Quality & Reliability Management, 33(1), 2-24. https://doi.org/10.1108/IJQRM-08-2013-0130

Deming, W. E. (1986). Out of the Crisis (1ª ed.). Cambridge: Massachusetts Inst Technology.

Faria S., C. E., Jardim, F. S., Camargo, V. C. B., Lizarelli, F. L., & Oprime, P. C. (2020). Unconditional performance of the X ̅ chart: Comparison among five standard deviation estimators. Quality and Reliability Engineering International, 36(5), 1808-1819. https://doi.org/10.1002/qre.2661

Finnerty, P., Provost, L., O’donnell, E., Selk, S., Stephens, K., Kim, J., & Berns, S. (2019). Using Infant Mortality Data to Improve Maternal and Child Health Programs: An Application of Statistical Process Control Techniques for Rare Events. Maternal and Child Health Journal, 23(6), 739–745. https://doi.org/10.1007/s10995-018-02710-3

Fonseca, L. A., Jr., Gomes, L. C. P., Santos, A. G., & Peruchi, R. S. (2019). Análise da percepção da satisfação dos clientes de uma empresa de produtos de máquinas e implementos agrícolas. Brazilian Journal of Production Engineering, 5(3), 1-18. https://doi.org/10.0001/V05N03_01

Haq, A. & Munir, W. (2021). New CUSUM and Shewhart-CUSUM chart for monitoring the process mean. Quality and Reliability Engineering International, 37(8), 3512-3528. https://doi.org/10.1002/qre.2930

Jardim, F. S., Chakraborti, S., & Epprecht, E. K. (2019). X ̅ Chart with Estimated Parameters: The Conditional ARL Distribution and New Insights. Production and Operations Management, 28(6), 1545–1557. https://doi.org/10.1111/poms.12985

Keller, D. S., Paula, T. R., Yu, G., Zhang, H., Al-Mazrou, A., & Kiran, R. P. (2020). Statistical Process Control (SPC) to drive improvement in length of stay after colorectal surgery. The American Journal of Surgery, 219(1), 1006-1011. https://doi.org/10.1016/j.amjsurg.2019.08.029

Kennedy, C. W., Hoffman E. G., & Bond S. D. (1987). Inspection and gaging (6ª ed.). NewYork: Industrial Press Inc.

Khan, M. Z., Khan, M. F., Aslam, M., Akhavan Niaki, S. T., & Mughal, A. R. (2018). A fuzzy EWMA attribute control chart to monitor process mean. Information (Switzerland), 9(12), 1-13. https://doi.org/10.3390/info9120312

Knauer, W. A., Godden, S. M., Dietrich, A., Hawkins, D. M., & James, R. E. (2018). Evaluation of applying statistical process control techniques to daily average feeding behaviors to detect disease in automatically fed group-housed preweaned dairy calves. Journal of Dairy Science, 101(9), 8135-8145. https://doi.org/10.3168/jds.2017-13947

Kottner, J. (2014). The value of Statistical Process Control in quality improvement contexts: Commentary on Unbeck et al. (2013). International Journal of Nursing Studies, 51(1), 346-349. https://doi.org/10.1016/j.ijnurstu.2013.04.011

Kringel, D. H., Dias, A. R. G., Zavareze, E. R., & Gandra, E. A. (2020). Fruit Wastes as Promising Sources of Starch: Extraction, Properties, and Applications. Starch ‐ Stärke, 72(3-4), 1-9. https://doi.org/10.1002/star.201900200

Lee, L. Y., Khoo, M. B. C., Teh, S. Y., & Lee, M. H. (2015). A variable sampling interval synthetic Xbar chart for the process mean. PLoS ONE, 10(5), 1-18. https://doi.org/10.1371/journal.pone.0126331

Lilliefors, H. W. (1967). On the Kolmogorov-Smirnov Test for Normality with Mean and Variance Unknown. Journal of the American Statistical Association, 62, 399-402. https://doi.org/10.2307/2283970

Lim, S. A. H., Antony, J., He, Z., & Arshed, N. (2017). Critical observations on the statistical process control implementation in the UK food industry: A survey. International Journal of Quality & Reliability, 34(5), 684-700. https://doi.org/10.1108/IJQRM-03-2015-0035

Mizaei, N., Niroomand, S., & Zare, R. (2016). Application of statistical process control in service industry. Journal of Modelling in Management, 11(3), 763-782. https://doi.org/10.1108/JM2-06-2014-0046

Montgomery, D. C. (2019). Introduction to Statistical Quality Control (7ª ed.). Nova Jersey: John Wiley & Sons.

Montgomery, D. C. & Runger, G. C. (2020). Applied Statistics and Probability for Engineers (6ª ed.). Nova Jersey: John Wiley & Sons.

Oakland, J. & Oakland, R. (2018). Statistical Process Control (7ª ed.). Nova Iorque: Routledge.

Oliveira, G. D., Santos, J. D., Silva, V. L., & Röder, C. (2018). Aplicação do controle estatístico do processo em uma indústria de autoadesivos. Exacta, 16(2), 135-154. https://doi.org/10.5585/exactaep.v16n2.7340

Peruchi, R. S., Rotela, P., Jr., Brito, T. G., Paiva, A. P., Balestrassi, P. P., & Araújo, L. M. M. (2020). Integrating multivariate statistical analysis into Six Sigma DMAIC projects: A case study on AISI 52100 hardened steel turning. IEEE Access, 8(1), 34246-34255. http://dx.doi.org/10.1109/ACCESS.2020.2973172

Polhemus, N. W. (2017). Process Capability Analysis (1ª ed.). Florida: CRC Press.

Prata, E. R. B. A., Chaves, J. B. P., Gomes, S. G. S., & Passos, F. J. V. (2020). Statistical quality control in the food industry: a risk-based approach. International Journal of Quality & Reliability Management, 38(2), 437-452. https://doi.org/10.1108/IJQRM-08-2019-0272

Raji, I. A., Lee, M. H., Riaz, M., Abujiya, M. R., Abbas, N. A robust multivariate Shewhart chart for contaminated normal environments. Quality and Reliability Engineering International, 37(6), 2665-2684. https://doi.org/10.1002/qre.2882

Riaz M., & Does R. J. M. M. (2009). A process variability control chart. Computational statistics, 24(2), 345–368. https://doi.org/10.1007/s00180-008-0122-z

Ross, J. E. (2017). Total Quality Management: Text, Cases and Readings (3ª ed.). Nova Iorque: Routledge.

Sahay, A. (2017). Process Capability Analysis for Quality and Lean Six Sigma (1ª ed). Nova Iorque: QMS Global LLC.

Shewhart, W. A. (1931). Economic Controlo of Quality of Manufactured Product (1ª ed). Nova Iorque: Van Nostrand.

Shewhart, W. A. (1939). Statistical Method from the Viewpoint of Quality Control (1ª ed). Whashington: Graduate School of the Department of Agriculture.

Soela, D. M., Vitória, E. L., Oliveira, R. F., Crause, D. H., Freitas, I. L. J., & Locatelli, T. (2020). Controle Estatístico de Processo em pulverização usando veículo aéreo não tripulado na cultura do café Conilon. Brazilian Journal of Production Engineering, 6(4), 52-63. https://periodicos.ufes.br/bjpe/article/view/30180/20928

Sower, V. E., Quarles, R., & Broussard, E. (2007). Cost of quality usage and its relationship to quality system maturity. International Journal of Quality & Reliability Management, 24(1), 121–140. https://doi.org/10.1108/02656710710722257

Sutterfield, J. S. & Daramola, T. R. (2016). Using the Tools of Quality to Improve Production Operations at Wilmington Textile. ProQuest, 9(2), 118-133. https://www.proquest.com/scholarly-journals/using-tools-quality-improve-production-operations/docview/2044296482/se-2

Vetter, T. R. & Morrice, D. (2019). Statistical Process Control: No Hots, No Runs, No Errors? Anesthesia and analgesia, 128(2), 374-382. https://doi.org/10.1213/ane.0000000000003977

Wiemken, T. L., Furmanek, S. P., Mattingly, W. A., Wright, M. O., Persaud, A. K., Guinn, B. E., Carrico, R. M., Arnold, F. W., & Ramirez, J. A. (2018). Methods for computational disease surveillance in infection prevention and control: Statistical process control versus Twitter's anomaly and breakout detection algorithms. American Journal of Infection Control, 46(2), 124-132. https://doi.org/10.1016/j.ajic.2017.08.005

Zerbato, C., Furlani, C. E. A., Ormond, A. T. S., Girio, L. A. S., Carneiro, F. M., & Silva, R. P. da (2017) Statistical process control applied to mechanized peanut sowing as a function of soil texture. (Research Article)(Report). PLoS ONE, 12(7), 1-14. https://doi.org/10.1371/journal.pone.0180399

Zhao, F., Chen, L., Xia, T., Ye, Z., & Zheng, Y. (2019). Gas turbine exhaust system health management based on recurrent neural networks. Procedia CIRP, 83, 630–635. https://doi.org/10.1016/j.procir.2019.04.122

Zhou, W., Cheng, C., & Zheng, Z. (2019). Optimal design of an attribute control chart for monitoring the mean of autocorrelated processes. Computers and Industrial Engineering, 137(January), 106081, 2019. http://dx.doi.org/10.1016/j.cie.2019.106081

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2022 Brazilian Journal of Production Engineering

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.