Dispositivos tecnológicos en orden Picking System: Revisión bibliográfica

DOI:

https://doi.org/10.47456/bjpe.v8i6.39192Palabras clave:

depósito, tecnología, innovación, : preparación de pedidosResumen

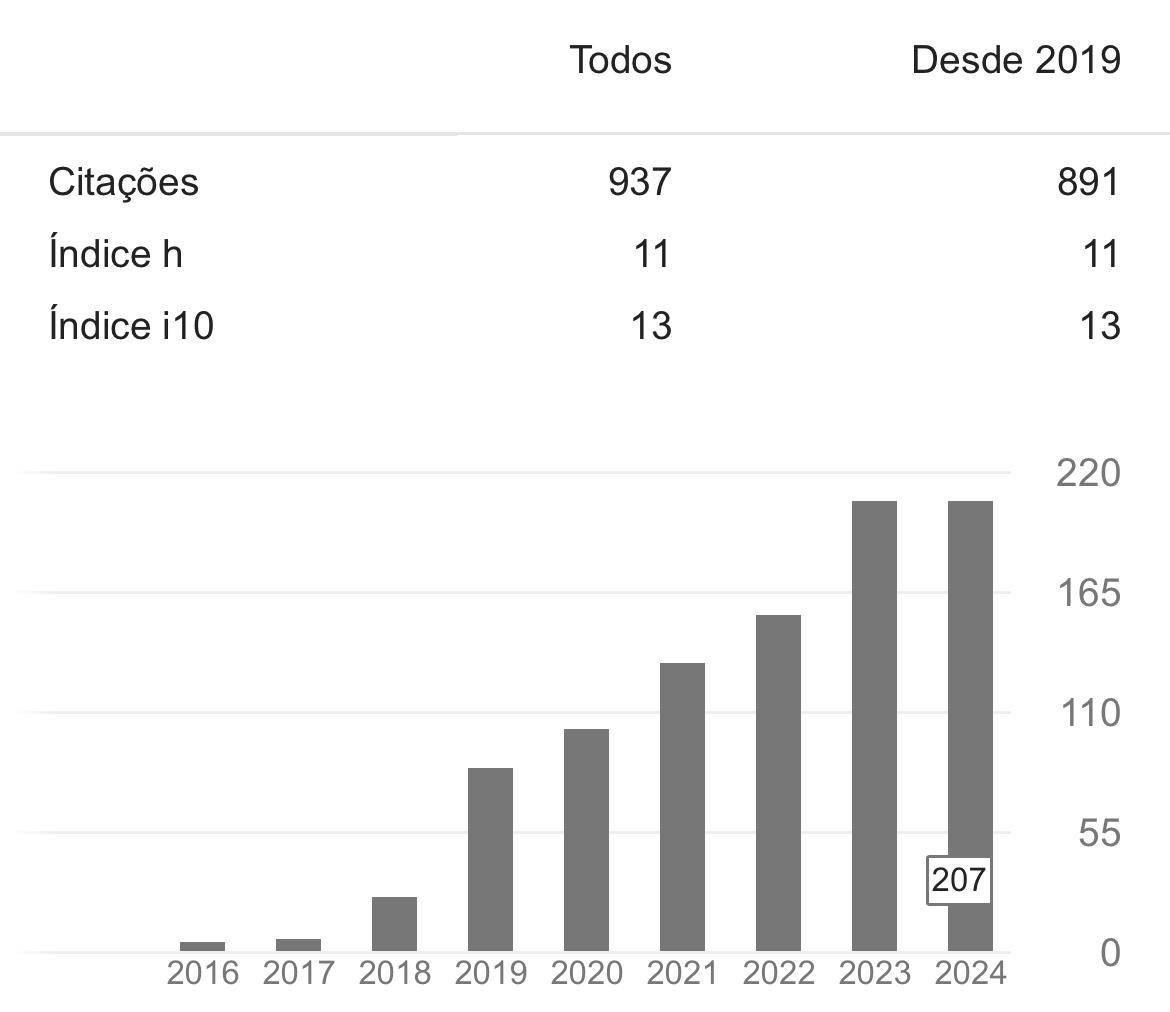

Debido al comportamiento cambiante de los consumidores, el almacén ha recibido una gran demanda de pedidos. La actividad de elección y recogida de pedidos se considera la más crítica. Estas son las actividades que tienen el costo más alto y la que demanda mayor tiempo. Para traer un mejor desempeño en estas actividades, muchos especialistas han recurrido a dispositivos tecnológicos. Este artículo trae una revisión literaria con el objetivo de identificar qué dispositivos se encuentran en los estudios científicos con el fin de satisfacer la demanda de recolección de pedidos, e identificar los factores estudiados para cada uno, así como identificar puntos de vista y las oportinidades para futuras investigaciones, o desarrollo de nuevos dispositivos. Para eso se analizaron 101 artículos que contaban con algún dispositivo en la recogida de pedidos. Estos artículos fueron separados y categorizados según su uso y características. Como resultado, es posible que los investigadores y los tomadores de decisiones conozcan los dispositivos estudiados y comprendan cómo se comportan. A través de esta investigación se puede concluir que el interés por el tema ha crecido considerablemente en los últimos dos años, y que es necesario tomar en cuenta algunos factores antes de elegir el dispositivo, ellos son: layout, SKU, modelo de despliegue e implementación.

Descargas

Citas

Andriansyah, R., Etman, L.F.P., Adan, J. B. F., & Rooda, J. E. (2014). Design and Analysis of an Automated Order-Picking Workstation. Journal of Simulation, 8(2), 151-163. https://doi.org/10.1057/jos.2013.24. DOI: https://doi.org/10.1057/jos.2013.24

Andriolo, A., Battini, D., Calzavara, M., Gamberi, M., Peretti, U., Persona A. Pilati, F., & Sgarbossa, F. (2016). New RFID pick-to-light system: Operating characteristics and future potential. International Journal of RF Technologies, 7(1), 43–63. https://doi.org/10.3233/RFT-150071. DOI: https://doi.org/10.3233/RFT-150071

Armstrong, R. D., Cook, W. D., & Saipe, A. L. (1979). Optimal Batching in a Semi-Automated Order Picking System. Journal of the Operational Research Society, 30(8), 711-720. https://doi.org/10.1057/jors.1979.173. DOI: https://doi.org/10.1057/jors.1979.173

Atchade-Adelomou, P. Alonso-Linaje, G. Albo-Canals, J. & Casado-Fauli, D. (2021). QRobot: A Quantum Computing Approach in Mobile Robot Order Picking and Batching Problem Solver Optimization. Algorithms, 14 (7), 194. https://doi.org/10.3390/a14070194. DOI: https://doi.org/10.3390/a14070194

Atmaca, E, & Ozturk, A. (2013). Defining Order Picking Policy: A Storage Assignment Model and a Simulated Annealing Solution in AS/RS Systems. Applied Mathematical Modelling, 37(7), 5069-5079. https://doi.org/10.1016/j.apm.2012.09.057. DOI: https://doi.org/10.1016/j.apm.2012.09.057

Bansal, V., Roy, D., & Pazour, J. A. (2021). Performance Analysis of Batching Decisions in Waveless Order Release Environments for E‐commerce Stock‐to‐picker Order Fulfillment. International Transactions in Operational Research, 28(4), 1787-1820. https://doi.org/10.1111/itor.12921. DOI: https://doi.org/10.1111/itor.12921

Battini D, Calzavara M,Persona A, & Sgarbossa F. (2017) A comparative analysis of different paperless picking systems. Industrial Management & Data Systems, 115(3), 483–503. https://doi.org/10.1108/IMDS-10-2014-0314. DOI: https://doi.org/10.1108/IMDS-10-2014-0314

Beinschob, P., Meyer, M., Reinke, C., Digani, V., Secchi, C., & Sabattini, L. (2017). Semi-Automated Map Creation for Fast Deployment of AGV Fleets in Modern Logistics. Robotics and Autonomous Systems, 87, 281–295. DOI.org (Crossref), https://doi.org/10.1016/j.robot.2016.10.018. DOI: https://doi.org/10.1016/j.robot.2016.10.018

Bolu, A. & Korcak, O. (2021). Adaptive Task Planning for Multi-Robot Smart Warehouse. IEEE Access, 9, 27346-27358. https://doi.org/10.1109/ACCESS.2021.3058190. DOI: https://doi.org/10.1109/ACCESS.2021.3058190

Bortolini, M., Faccio, M., Ferrari, E., Gamberi, M., & Pilati F. (2017). Time and Energy Optimal Unit-Load Assignment for Automatic S/R Warehouses. International Journal of Production Economics, 190, 133-145. https://doi.org/10.1016/j.ijpe.2016.07.024. DOI: https://doi.org/10.1016/j.ijpe.2016.07.024

Boysen, N., Fedtke, S., & Weidinger, F. (2018). Optimizing Automated Sorting in Warehouses: The Minimum Order Spread Sequencing Problem. European Journal of Operational Research, 270(1), 386–400. https://doi.org/10.1016/j.ejor.2018.03.026. DOI: https://doi.org/10.1016/j.ejor.2018.03.026

Boysen, N., Briskorn, D., & Emde, S. (2017A). Parts-to-Picker Based Order Processing in a Rack-Moving Mobile Robots Environment. European Journal of Operational Research, 262(2), 550-562. https://doi.org/10.1016/j.ejor.2017.03.053. DOI: https://doi.org/10.1016/j.ejor.2017.03.053

Boysen, N., FüBler, D., & Stephan K. (2020). See the Light: Optimization of Put‐to‐light Order Picking Systems. Naval Research Logistics (NRL), 67 (1), 3–20. https://doi.org/10.1002/nav.21883. DOI: https://doi.org/10.1002/nav.21883

Boysen, N., Briskorn, D., & Emde, S. (2017B). Sequencing of Picking Orders in Mobile Rack Warehouses. European Journal of Operational Research, 259(1), 293–307. https://doi.org/10.1016/j.ejor.2016.09.046. DOI: https://doi.org/10.1016/j.ejor.2016.09.046

Bozer, Y. A., & Aldarondo, F.J. (2018). A Simulation-Based Comparison of Two Goods-to-Person Order cking Systems in an Online Retail Setting. International Journal of Production Research, 56 (11), 3838–3858. https://doi.org/10.1080/00207543.2018.1424364. DOI: https://doi.org/10.1080/00207543.2018.1424364

Cai, J., Li, X., Liang, Y., & Ouyang, S. (2021). Collaborative Optimization of Storage Location Assignment and Path Planning in Robotic Mobile Fulfillment Systems. Sustainability, 13(10), 5644. https://doi.org/10.3390/su13105644. DOI: https://doi.org/10.3390/su13105644

Calzavara, M., Sgarbossa, F., & Persona, A. (2019). Vertical Lift Modules for Small Items Order Picking: An Economic Evaluation. International Journal of Production Economics, 210, 199–210. https://doi.org/10.1016/j.ijpe.2019.01.012. DOI: https://doi.org/10.1016/j.ijpe.2019.01.012

Cao, W., Jiang, P., Liu, B., & Jiang, K. (2018). Real-Time Order Scheduling and Execution Monitoring in Public Warehouses Based on Radio Frequency Identification. The International Journal of Advanced Manufacturing Technology, 95(5), 2473-2494. https://doi.org/10.1007/s00170-017-1381-z. DOI: https://doi.org/10.1007/s00170-017-1381-z

Chang, D. T., Wen, U. P., & Lin, J. T. (1993). Picking Strategies to the Two‐carousel‐single‐server System in an Automated Warehouse. Journal of the Chinese Institute of Engineers, 16(6), 817-824. https://doi.org/10.1080/02533839.1993.9677556. DOI: https://doi.org/10.1080/02533839.1993.9677556

Choy, K. L., Ho, G. T. S., & Lee, C. K. H. (2017). A RFID-Based Storage Assignment System for Enhancing the Efficiency of Order Picking. Journal of Intelligent Manufacturing, 28(1), 111–129. https://doi.org/10.1007/s10845-014-0965-9. DOI: https://doi.org/10.1007/s10845-014-0965-9

Correll, N., Bekris, K. E., Berenson, D., Brock, O., Causo, A., Hauser, K., Okada, k., Rodriguez, A., Romano, J. R., & Wurman, P. R. (2018). Analysis and observations from the first amazon picking challenge. IEEE Transactions on Automation Science and Engineering, 15(1), 172-188. https://doi.org/10.1109/TASE.2016.2600527. DOI: https://doi.org/10.1109/TASE.2016.2600527

Custodio, L., & Machado, R. (2020). Flexible automated warehouse: A literature review and an innovative framework. The International Journal of Advanced Manufacturing Technology, 106 (1), 533–558. https://doi.org/10.1007/s00170-019-04588-z. DOI: https://doi.org/10.1007/s00170-019-04588-z

D’Avella, S., Tripicchio, P., & Avizzano, C. A. (2020). A Study on Picking Objects in Cluttered Environments: Exploiting Depth Features for a Custom Low-Cost Universal Jamming Gripper. Robotics and Computer-Integrated Manufacturing, 63, 101888. https://doi.org/10.1016/j.rcim.2019.101888. DOI: https://doi.org/10.1016/j.rcim.2019.101888

D’Souza, F., Costa, J., & Pires, J. N. (2020). Development of a solution for adding a collaborative robot to an industrial AGV. Industrial Robot: the international journal of robotics research and application, 47(5), 723-735. https://doi.org/10.1108/IR-01-2020-0004. DOI: https://doi.org/10.1108/IR-01-2020-0004

De Koster, R., Le-Duc, T., & Roodbergen, K. J. (2007) Design and Control of Warehouse Order Picking: A Literature Review. European Journal of Operational Research, 182(2), 481–501. https://doi.org/10.1016/j.ejor.2006.07.009. DOI: https://doi.org/10.1016/j.ejor.2006.07.009

De Vries, J., De Koste, R., & Stam D. (2016). Exploring the Role of Picker Personality in Predicting Picking Performance with Pick by Voice, Pick to Light and RF-Terminal Picking. International Journal of Production Research, 54(8), 2260–2274. https://doi.org/10.1080/00207543.2015.1064184. DOI: https://doi.org/10.1080/00207543.2015.1064184

Department of Financial and Management Engineering, School of Engineering, University of the Aegean, Chios, Greece, (2020). Testing vision picking technology in warehouse operations: Evidence from laboratory experiments. International Journal of Industrial Engineering and Management, 11(1), 19–30. https://doi.org/10.24867/IJIEM-2020-1-249. DOI: https://doi.org/10.24867/IJIEM-2020-1-249

Dukic, G., Opetuk, T., Lerher, T. (2015). A throughput model for a dual-tray Vertical lift Module with a human order picker. International Journal of Production Economics, 170, 874-881. https://doi.org/10.1016/j.ijpe.2015.04.009. DOI: https://doi.org/10.1016/j.ijpe.2015.04.009

Elsayed, E. A., & Stern, R.G. (1983). Computerized Algorithms for Order Processing in Automated Warehousing Systems. International Journal of Production Research, 21(4), 579–586. https://doi.org/10.1080/00207548308942392. DOI: https://doi.org/10.1080/00207548308942392

Fager, P., Sgarbossa, F., & Calzavara, M. (2021). Cost Modelling of Onboard Cobot-Supported Item Sorting in a Picking System. International Journal of Production Research, 59(11), 3269-3284. https://doi.org/10.1080/00207543.2020.1854484. DOI: https://doi.org/10.1080/00207543.2020.1854484

Fang, W., & An, Z. (2020). A Scalable Wearable AR System for Manual Order Picking Based on Warehouse Floor-Related Navigation. The International Journal of Advanced Manufacturing Technology, 109(7), 2023-2037. https://doi.org/10.1007/s00170-020-05771-3. DOI: https://doi.org/10.1007/s00170-020-05771-3

Fontin, J. R., & Lin, S. W. (2020). A Joint Comparative Analysis of Routing Heuristics and Paperless Picking Technologies Using Simulation and Data Envelopment Analysis. Applied Sciences, 10(24), 8777. https://doi.org/10.3390/app10248777. DOI: https://doi.org/10.3390/app10248777

Foroughi, A., Boysen, N., Emde, S., & Schneider M. (2021). High-Density Storage with Mobile Racks: Picker Routing and Product Location. Journal of the Operational Research Society, 72(3), 535-553. https://doi.org/10.1080/01605682.2019.1700180. DOI: https://doi.org/10.1080/01605682.2019.1700180

Füchtenhans, M., Grosse E. H., & Glock C. H. (2021). Smart Lighting Systems: State-of-the-Art and Potential Applications in Warehouse Order Picking. International Journal of Production Research, 59 (12), 3817–3839. https://doi.org/10.1080/00207543.2021.1897177. DOI: https://doi.org/10.1080/00207543.2021.1897177

Gajšek, B., Ðukić, G., Butlewski, M., Opetuk, T., Cajner, H., & Kač, S.M. (2020). The Impact of the Applied Technology on Health and Productivity in Manual ‘Picker-to-Part’ Systems. Work, 65(3), 525–536. https://doi.org/10.3233/WOR-203107. DOI: https://doi.org/10.3233/WOR-203107

Gong, Y. Jin, M., & Yuan Z. (2021). Robotic Mobile Fulfilment Systems Considering Customer Classes. International Journal of Production Research, 59(16), 5032-5049. https://doi.org/10.1080/00207543.2020.1779370. DOI: https://doi.org/10.1080/00207543.2020.1779370

Guo, A., Wu, X., Shen, Z., Starner, T., Baumann, H., & Gililand, S. (2015). Order Picking with Head-Up Displays. Computer, 48(6), 16–24. https://doi.org/10.1109/MC.2015.166. DOI: https://doi.org/10.1109/MC.2015.166

Habazin, J., Gasnovic, A., & Bajor I. (2017). Order Picking Process in Warehouse: Case Study of Dairy Industry in Croatia. Promet - Traffic&Transportation, 29(1), 57–65. https://doi.org/10.7307/ptt.v29i1.2106. DOI: https://doi.org/10.7307/ptt.v29i1.2106

Hanson, R., Falkenstrõm, W., & Miettinen, M. (2017). Augmented Reality as a Means of Conveying Picking Information in Kit Preparation for Mixed-Model Assembly. Computers & Industrial Engineering, 113, 570-575. https://doi.org/10.1016/j.cie.2017.09.048. DOI: https://doi.org/10.1016/j.cie.2017.09.048

He, Z., Aggarwal, V., & Nof, S. Y. (2018). Differentiated Service Policy in Smart Warehouse Automation. International Journal of Production Research, 56(22), 6956-6970. https://doi.org/10.1080/00207543.2017.1421789. DOI: https://doi.org/10.1080/00207543.2017.1421789

Hou, J. L., Wu, N., & Wu, Y. J. (2009). A Job Assignment Model for Conveyor-Aided Picking System. Computers & Industrial Engineering, 56(4), 1254-1264. https://doi.org/10.1016/j.cie.2008.07.017. DOI: https://doi.org/10.1016/j.cie.2008.07.017

Hwang, H., Baek, W. J., & Lee, M. K. (1988). Clustering Algorithms for Order Picking in an Automated Storage and Retrieval System. International Journal of Production Research, 26(2), 189–201. https://doi.org/10.1080/00207548808947853. DOI: https://doi.org/10.1080/00207548808947853

Jaghbeer, Y., Hanson, R., Johansson, M. I. (2020). Automated Order Picking Systems and the Links between Design and Performance: A Systematic Literature Review. International Journal of Production Research, 58 (15), 4489–4505. https://doi.org/10.1080/00207543.2020.1788734. DOI: https://doi.org/10.1080/00207543.2020.1788734

Jerman, B., Ekren, B.Y., Küxükyasar, M., & Lerher, T. (2021). Simulation-Based Performance Analysis for a Novel AVS/RS Technology with Movable Lifts. Applied Sciences, 11(5), 22-83. www.mdpi.com, https://doi.org/10.3390/app11052283. DOI: https://doi.org/10.3390/app11052283

Jiang, H. (2020). Solving Multi-Robot Picking Problem in Warehouses: A Simulation Approach. International Journal of Simulation Modelling, 19 (4), 701-712. https://doi.org/10.2507/IJSIMM19-4-CO19. DOI: https://doi.org/10.2507/IJSIMM19-4-CO19

Jiang, Z. Z., Wan, M., Pei, Z., & Qin, X. (2021). Spatial and Temporal Optimization for Smart Warehouses with Fast Turnover. Computers & Operations Research, 125, 105091. https://doi.org/10.1016/j.cor.2020.105091. DOI: https://doi.org/10.1016/j.cor.2020.105091

Kaipa, K. N., Kankanhalli-nagendra, A. S., Kumbla, N. B., Shriyam, S., Thevendria-karthic, S., Mavel, J. A., Gupta, S. K., Addressing Perception Uncertainty Induced Failure Modes in Robotic Bin-Picking. Robotics and Computer-Integrated Manufacturing, 42, 17–38. https://doi.org/10.1016/j.rcim.2016.05.002. DOI: https://doi.org/10.1016/j.rcim.2016.05.002

Keung, K. L., Lee, C. K. M., Ji, P., & Ng, K. K. H. (2020). Cloud-Based Cyber-Physical Robotic Mobile Fulfillment Systems: A Case Study of Collision Avoidance. IEEE Access, 8, 89318-89336. https://doi.org/10.1109/ACCESS.2020.2992475. DOI: https://doi.org/10.1109/ACCESS.2020.2992475

Khachatryan, M., & McGinnis, L. F. (2014). Picker Travel Time Model for an Order Picking System with Buffers. IIE Transactions, 46(9), 894–904. https://doi.org/10.1080/0740817X.2013.823001. DOI: https://doi.org/10.1080/0740817X.2013.823001

Khojasteh, Y., & Son, J. D. (2016). A Travel Time Model for Order Picking Systems in Automated Warehouses. The International Journal of Advanced Manufacturing Technology, 86(5), 2219-2229. https://doi.org/10.1007/s00170-016-8340-y. DOI: https://doi.org/10.1007/s00170-016-8340-y

Kim, B. I., Heragu, S. S., Graves, R. J., & Onge, A. S. (2003). Clustering-Based Order-Picking Sequence Algorithm for an Automated Warehouse. International Journal of Production Research, 41(15), 3445-3460. https://doi.org/10.1080/0020754031000120005. DOI: https://doi.org/10.1080/0020754031000120005

Kim, H. J., Pais, C., & Shen, Z. J. M. (2020). Item Assignment Problem in a Robotic Mobile Fulfillment System. IEEE Transactions on Automation Science and Engineering, 17(4), 1854-1867. https://doi.org/10.1109/TASE.2020.2979897. DOI: https://doi.org/10.1109/TASE.2020.2979897

Kim, Y., & Hong, S (2020). Two Picker Cooperation Strategies for Zone Picking Systems with PTL Technology. IEEE Access, 8, 106059-106070. https://doi.org/10.1109/ACCESS.2020.2999342. DOI: https://doi.org/10.1109/ACCESS.2020.2999342

Kong, X. T. R., Yang, X., Peng, K. L., & Li, C. Z. (2020). Cyber Physical System-Enabled Synchronization Mechanism for Pick-and-Sort Ecommerce Order Fulfilment. Computers in Industry, 118, 103-220. https://doi.org/10.1016/j.compind.2020.103220. DOI: https://doi.org/10.1016/j.compind.2020.103220

Krug, R., Stoyanov, T., Tincani, V., Andreasso, H., Mosberger, R., Fantoni, G., & Lilienthal, A. (2016). The Next Step in Robot Commissioning: Autonomous Picking and Palletizing. IEEE Robotics and Automation Letters, 1 (1), 546-553. https://doi.org/10.1109/LRA.2016.2519944. DOI: https://doi.org/10.1109/LRA.2016.2519944

Kudelska, I., & Niedbał, R. (2020) Technological and Organizational Innovation in Warehousing Process – Research over Workload of Staff and Efficiency of Picking Stations. E+M Ekonomie a Management, 23 (3), 67–81. https://doi.org/10.15240/tul/001/2020-3-005. DOI: https://doi.org/10.15240/tul/001/2020-3-005

Lamballais, T., Roy, D., & De Koster, R. B. M. (2020). Inventory Allocation in Robotic Mobile Fulfillment Systems. IISE Transactions, 52(1), 1–17. https://doi.org/10.1080/24725854.2018.1560517. DOI: https://doi.org/10.1080/24725854.2018.1560517

Lamballais, T., Roy, D., & De Koster R. B. M. (2017). Estimating Performance in a Robotic Mobile Fulfillment System. European Journal of Operational Research, 256(3), 976-990. https://doi.org/10.1016/j.ejor.2016.06.063. DOI: https://doi.org/10.1016/j.ejor.2016.06.063

Latif, U. K., & Shin, S. Y. (2020). OP-MR: The Implementation of Order Picking Based on Mixed Reality in a Smart Warehouse. The Visual Computer, 36(7), 1491-1500. https://doi.org/10.1007/s00371-019-01745-z. DOI: https://doi.org/10.1007/s00371-019-01745-z

Lee, H. Y., & Murray, C. C. (2019). Robotics in Order Picking: Evaluating Warehouse Layouts for Pick, Place, and Transport Vehicle Routing Systems. International Journal of Production Research, 57(18), 5821-4841. https://doi.org/10.1080/00207543.2018.1552031. DOI: https://doi.org/10.1080/00207543.2018.1552031

Lee, J. A., Chang, Y. S., & Karwowski, W. (2020). Assessment of working postures and physical loading in advanced order picking tasks: A case study of human interaction with automated warehouse goods-to-picker systems. Work, 67(4), 855-866. https://doi.org/10.3233/WOR-203337. DOI: https://doi.org/10.3233/WOR-203337

Lee, S. D., & Kuo Y.C. (2008) Exact and Inexact Solution Procedures for the Order Picking in an Automated Carousal Conveyor. International Journal of Production Research, 46 (16), 4619–4636. https://doi.org/10.1080/00207540601166990. DOI: https://doi.org/10.1080/00207540601166990

Liu, D. Zhao X, Wang Y. (2019). Items Assignment Optimization for Complex Automated Picking Systems. Cluster Computing, 22 (3). Springer Link, https://doi.org/10.1007/s10586-017-1529-5. DOI: https://doi.org/10.1007/s10586-017-1529-5

Liu, D. Mou, S. Wu, Y. Shan, G. (2015). Research on Hybrid Picking Strategy in an Automated Order Picking System. International Journal of Control and Automation, 8 (8). DOI.org (Crossref), https://doi.org/10.14257/ijca.2015.8.8.12. DOI: https://doi.org/10.14257/ijca.2015.8.8.12

Liu, J. E. Zhang, S. Liu, H. (2019). Research on AGV Path Planning under ‘Parts-to-Picker’ Mode. Open Journal of Social Sciences, 07 (6), 1–14. DOI.org (Crossref), https://doi.org/10.4236/jss.2019.76001. DOI: https://doi.org/10.4236/jss.2019.76001

Marchet G, Melacini M, Perotti S. (2015) Investigating Order Picking System Adoption: A Case-Study-Based Approach. International Journal of Logistics Research and Applications, 18 (1), 82–98. DOI.org (Crossref), https://doi.org/10.1080/13675567.2014.945400. DOI: https://doi.org/10.1080/13675567.2014.945400

Mnyusiwalla, H. Triantafyllou, P. Sotiropoulos, P. Roa, M.A. Fried, W. Sundaram, A.M. Russell, D. Deacon, G. (2020). A Bin-Picking Benchmark for Systematic Evaluation of Robotic Pick-and-Place Systems. IEEE Robotics and Automation Letters, 5 (2). DOI.org (Crossref), https://doi.org/10.1109/LRA.2020.2965076. DOI: https://doi.org/10.1109/LRA.2020.2965076

Nicolas, L. Yannick, F. Ramzi. H. (2018). Order Batching in an Automated Warehouse with Several Vertical Lift Modules: Optimization and Experiments with Real Data. European Journal of Operational Research, 267 (3). DOI.org (Crossref), https://doi.org/10.1016/j.ejor.2017.12.037. DOI: https://doi.org/10.1016/j.ejor.2017.12.037

Park, B. C. Frazelle, E. H. White, J. A. (1999). Buffer sizing models for end-of-aisle order picking systems. IIE Transactions, 31 (1). DOI.org (Crossref), https://doi.org/10.1023/A:1007520600713. DOI: https://doi.org/10.1080/07408179908969803

Polten, L, & Emde, S. (2021). Scheduling Automated Guided Vehicles in Very Narrow Aisle Warehouses. Omega, 99. DOI.org (Crossref), https://doi.org/10.1016/j.omega.2020.102204. DOI: https://doi.org/10.1016/j.omega.2020.102204

Poon, T.C. Choy, K.L. Chow, H.K.H. Lau, H.C.W. Chan, F.T.S. Ho, K.C. (2009). A RFID Case-Based Logistics Resource Management System for Managing Order-Picking Operations in Warehouses. Expert Systems with Applications, 36 (4). DOI.org (Crossref), https://doi.org/10.1016/j.eswa.2008.10.011. DOI: https://doi.org/10.1016/j.eswa.2008.10.011

Rajotia, S. Shanker, K. Batra, J. L. (1998). Determination of Optimal AGV Fleet Size for an FMS. International Journal of Production Research, 36 (5). DOI.org (Crossref), https://doi.org/10.1080/002075498193273. DOI: https://doi.org/10.1080/002075498193273

Ramtin, F. & Pazour, J. A. (2014). Analytical models for an automated storage and retrieval system with multiple in-the-aisle pick positions. IIE Transactions, 46 (9). https://doi.org/10.1080/0740817X.2014.882037. DOI: https://doi.org/10.1080/0740817X.2014.882037

Ramtin, F. & Pazour, J. A. (2015). Product Allocation Problem for an AS/RS with Multiple in-the-Aisle Pick Positions. IIE Transactions, 47 (12). DOI.org (Crossref), https://doi.org/10.1080/0740817X.2015.1027458. DOI: https://doi.org/10.1080/0740817X.2015.1027458

Reif, R. Günthner, W. A. Schwerdtfeger, B. Klinker, G. (2010). Evaluation of an Augmented Reality Supported Picking System Under Practical Conditions. Computer Graphics Forum, 29 (1), 2–12. DOI.org (Crossref), https://doi.org/10.1111/j.1467-8659.2009.01538.x. DOI: https://doi.org/10.1111/j.1467-8659.2009.01538.x

Reif, R. & Günthener, W. A. (2009). Pick-by-Vision: Augmented Reality Supported Order Picking. The Visual Computer, 25 (5). Springer Link, https://doi.org/10.1007/s00371-009-0348-y. DOI: https://doi.org/10.1007/s00371-009-0348-y

Roodbergen, K. J. & Vis, I. F. A. (2009). A Survey of Literature on Automated Storage and Retrieval Systems. European Journal of Operational Research, 194 (2). DOI.org (Crossref), https://doi.org/10.1016/j.ejor.2008.01.038. DOI: https://doi.org/10.1016/j.ejor.2008.01.038

Roy, D. Nigam, S. De koster, R. Adan, I. Resing J. (2019). Robot-Storage Zone Assignment Strategies in Mobile Fulfillment Systems. Transportation Research Part E: Logistics and Transportation Review, 122. DOI.org (Crossref), https://doi.org/10.1016/j.tre.2018.11.005. DOI: https://doi.org/10.1016/j.tre.2018.11.005

Schwerdtfeger, B. Reif, R. Günthner, W. A. Klinker, G. (2011). Pick-by-Vision: There Is Something to Pick at the End of the Augmented Tunnel. Virtual Reality, 15 (2). Springer Link, https://doi.org/10.1007/s10055-011-0187-9. DOI: https://doi.org/10.1007/s10055-011-0187-9

Sgarbossa, F. Calzavara, M. Persona, A. (2019). Throughput models for a dual-bay VLM order picking system under different configurations. Industrial Management & Data Systems, 119 (6). https://doi.org/10.1108/IMDS-11-2018-0518. DOI: https://doi.org/10.1108/IMDS-11-2018-0518

Tang, H., Cheng, X., Jiang, W., & Chen, S. (2021). Research on Equipment Configuration Optimization of AGV Unmanned Warehouse. IEEE Access, 9, 47946-47959. https://doi.org/10.1109/ACCESS.2021.3066622. DOI: https://doi.org/10.1109/ACCESS.2021.3066622

Tappia, E., Roy, D., Melacini, M., & De koster, R. (2019). Integrated Storage-Order Picking Systems: Technology, Performance Models, and Design Insights. European Journal of Operational Research, 274(3) 947–965. https://doi.org/10.1016/j.ejor.2018.10.048. DOI: https://doi.org/10.1016/j.ejor.2018.10.048

Tu, M., Yang, M. F., Kao, S. L., Lin, F. C., Wu M. H., & Lin, C. K. (2021). Using a Heuristic Multi-Objective Genetic Algorithm to Solve the Storage Assignment Problem for CPS-Based Pick-and-Pass System. Enterprise Information Systems, 15 (9), 1238-1259. https://doi.org/10.1080/17517575.2020.1811388. DOI: https://doi.org/10.1080/17517575.2020.1811388

Valle, C. A., & Beasley, J. E. (2021). Order Allocation, Rack Allocation and Rack Sequencing for Pickers in a Mobile Rack Environment. Computers & Operations Research, 125, 105090. https://doi.org/10.1016/j.cor.2020.105090. DOI: https://doi.org/10.1016/j.cor.2020.105090

Venkitasubramony, R., & Adil, G. K. (2017). Design of an Order-Picking Warehouse Factoring Vertical Travel and Space Sharing. The International Journal of Advanced Manufacturing Technology, 91(5), 1921–1934. https://doi.org/10.1007/s00170-016-9879-3. DOI: https://doi.org/10.1007/s00170-016-9879-3

Wang, Y., Shandong, M., & Changpeng, S. (2014). Selecting between Pick-and-sort System and Carousel System Based on Order Clustering and Genetic Algorithm. International Journal of Control and Automation, 7 (3), 89–102. https://doi.org/10.14257/ijca.2014.7.4.09. DOI: https://doi.org/10.14257/ijca.2014.7.4.09

Wang, Z., Sheu, J. B., Teo, C. P., & Xue, G. (2021). Robot Scheduling for Mobile‐Rack Warehouses: Human–Robot Coordinated Order Picking Systems. Production and Operations Management. 31(1), 98-116. https://doi.org/10.1111/poms.13406. DOI: https://doi.org/10.1111/poms.13406

Weidinger, F., Boysen, N., & Briskorn, D. (2018). Storage Assignment with Rack-Moving Mobile Robots in KIVA Warehouses. Transportation Science, 52(6), 1479-1495. https://doi.org/10.1287/trsc.2018.0826. DOI: https://doi.org/10.1287/trsc.2018.0826

Winkelhaus, S., Grosse, E. H., & Morana S. (2021) Towards a Conceptualisation of Order Picking 4.0. Computers & Industrial Engineering, 159, 107511. https://doi.org/10.1016/j.cie.2021.107511. DOI: https://doi.org/10.1016/j.cie.2021.107511

Wu, S., Chi, C., Wang, W., & Wu, Y. (2020). Research of the Layout Optimization in Robotic Mobile Fulfillment Systems. International Journal of Advanced Robotic Systems, 17(6). https://doi.org/10.1177/1729881420978543. DOI: https://doi.org/10.1177/1729881420978543

Wu, Y. & Wu, Y. (2014). Taboo Search Algorithm for Item Assignment in Synchronized Zone Automated Order Picking System. Chinese Journal of Mechanical Engineering, 27(4), 860-866. https://doi.org/10.3901/CJME.2014.0430.084. DOI: https://doi.org/10.3901/CJME.2014.0430.084

Wu, Y., Zhou, C., Wu, Y., & Kong, X. T. R. (2017). Zone Merge Sequencing in an Automated Order Picking System. International Journal of Production Research, 55(21), 6500-6515. https://doi.org/10.1080/00207543.2016.1264641. DOI: https://doi.org/10.1080/00207543.2016.1264641

Xie, L., Thieme, N., Krenzler, R., & Li, H. (2021). Introducing Split Orders and Optimizing Operational Policies in Robotic Mobile Fulfillment Systems. European Journal of Operational Research, 288(1), 80–97. https://doi.org/10.1016/j.ejor.2020.05.032. DOI: https://doi.org/10.1016/j.ejor.2020.05.032

Xing, L., Liu, Y., Li, H., Wu, C. C., & Lin, W. C., & Chen, X. (2020). A Novel Tabu Search Algorithm for Multi-AGV Routing Problem. Mathematics, 8(2), 279. https://doi.org/10.3390/math8020279. DOI: https://doi.org/10.3390/math8020279

Yang, D., Wu, Y., & Huo D, (2021). Research on Design of Cross-Aisles Shuttle-Based Storage/Retrieval System Based on Improved Particle Swarm Optimization. IEEE Access, 9, 67786-67796. https://doi.org/10.1109/ACCESS.2021.3077974. DOI: https://doi.org/10.1109/ACCESS.2021.3077974

Yoshitake, H., Kamoshida, R., & Nagashima, Y. (2019). New Automated Guided Vehicle System Using Real-Time Holonic Scheduling for Warehouse Picking. IEEE Robotics and Automation Letters, 4(2), 1045-1052. https://doi.org/10.1109/LRA.2019.2894001. DOI: https://doi.org/10.1109/LRA.2019.2894001

Yuan, Z. & Gong, Y. Y. (2017). Bot-In-Time Delivery for Robotic Mobile Fulfillment Systems. IEEE Transactions on Engineering Management, 64(1), 83–93. https://doi.org/10.1109/TEM.2016.2634540. DOI: https://doi.org/10.1109/TEM.2016.2634540

Zhuang, Z., Huang, Z., Sun, Y., & Qin, W. (2021). Optimization for Cooperative Task Planning of Heterogeneous Multi-Robot Systems in an Order Picking Warehouse. Engineering Optimization, 53(10), 1715-1732. https://doi.org/10.1080/0305215X.2020.1821198. DOI: https://doi.org/10.1080/0305215X.2020.1821198

Zou, B., Gong, Y., Xu, X., & Yuan. Z. (2017). Assignment rules in robotic mobile fulfilment systems for online retailers. International Journal of Production Research, 55(20), 6175-6192. https://doi.org/10.1080/00207543.2017.1331050. DOI: https://doi.org/10.1080/00207543.2017.1331050

Zou, B. Xu, X., Gong, Y., & De koster, R. (2018). Evaluating Battery Charging and Swapping Strategies in a Robotic Mobile Fulfillment System. European Journal of Operational Research, 267(2), 733-753. https://doi.org/10.1016/j.ejor.2017.12.008 DOI: https://doi.org/10.1016/j.ejor.2017.12.008

Xue, F., Tang, H., Su, Q., & Li, T. (2019). Task Allocation of Intelligent Warehouse Picking System based on Multi-robot Coalition. KSII Transactions on Internet and Information Systems, 13(7), 3566-3582. DOI: https://doi.org/10.3837/tiis.2019.07.013

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2022 Brazilian Journal of Production Engineering

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.