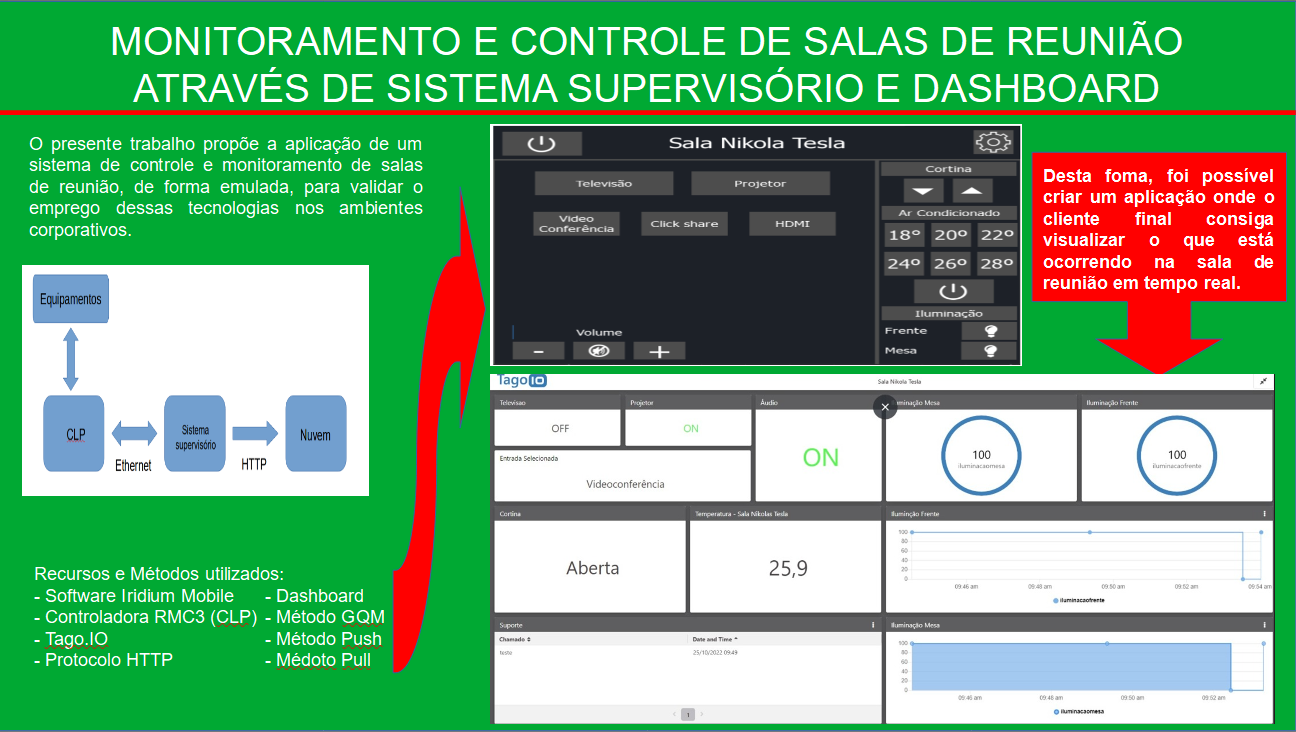

Monitoring and control of meeting rooms through a supervisory system and dashboard

DOI:

https://doi.org/10.47456/bjpe.v9i3.41490Keywords:

Control System, Monitoring, Meeting Room, Iridium Mobile, IOT, Supervisory, DashboardAbstract

The present work proposes the application of a control and monitoring system for meeting rooms, in an emulated form, to validate the use of these technologies in corporate environments, helping managers, technicians and companies in the maintenance of these environments that, with the advent of the home office and collaborative spaces, are becoming increasingly important within companies. In this work, the IRIDIUM MOBILE software was used to create the supervisory system that acts as a controller and gateway, sending information to the Tago.IO platform, through the HTTP protocol, to create a graphical interface (dashboard) for the team Responsible for room maintenance. The RMC3 controller, from Crestron, was used to act as a Programmable Logic Controller in the system designed for the meeting room, controlling the Boolean variables that indicate the status of the equipment (monitor, projector, video matrix, air conditioning, curtains and lighting). The work allowed showing, in a clear and precise way, the use of equipment in a meeting room, where the end user can have an idea of what is happening in the environment and proved to be effective in terms of updating time in the cloud, less than 0.5s.

Downloads

References

Andrade, C. (1996). Novos Conceitos de Ocupação de Espaços de Escritórios Territoriais ou Não-territoriais. Office. (22)

Janes A., Sillitti, A. & Succi G. (2016). Effective Dashboard Design

Ashton, K. (2009). That ‘internet of things’ thing. RFID journal, 22(7), 97-114.

Basili, V. R., Caldeira, Gianluigi., Rombach, H.D. (1994). The goal question metric approach. Recuperado de https://www.semanticscholar.org/paper/The-Goal-Question-Metric-Approach-Basili-Caldiera/02e65151786574852007ecd007ee270c50470af0

Iridium Mobile. https://iridi.com Acessado em: 8 abril 2022

Janes, A. & Succi, G. (2009), To Pull or Not to Pull. Conference Paper. https://doi.org/ 10.1145/1639950.1640052 DOI: https://doi.org/10.1145/1639950.1640052

Jurizato, L. A., & Pereira, P. S. R. (2003). Sistemas supervisórios. Nova odessa, network Technologies, 1, 2.

Lautier, François (1999). La gestion de la ressource spatiale. Laboratoire Espaces Travail (LET). 1-25. Recuperado de https://let.archi.fr/IMG/pdf/pub-let-article-ressource-spatiale.pdf

Lopes, Y. M. & Moori, R. G. (2021). O papel da IoT na relação entre gestão estratégica da logística e desempenho operacional. Revista de Administração Mackenzie, 22(3), 1-27. https://doi:10.1590/1678-6971/eRAMR210032 DOI: https://doi.org/10.1590/1678-6971/eramr210032

Malik, S. (2005). Enterprise dashboards: design and best practices for IT. John Wiley & Sons.

Moço, L. P. L, (2015). Análise do Desempenho de invocações à web services consumidos por um aplicativo móvel. (Trabalho de Diplomação). Universidade Tecnológica Federal do Paraná - UTFPR, Medianeira, PR, Brasil.

Okoh. C., Roy, R., & Mehnen, J. (2017). Maintenance Informatics Dashboard Design for Through-Life Engineering Services. Elsevier, 166-171 DOI: https://doi.org/10.1016/j.procir.2016.09.019

Paiola, C. E. G. (2018). O papel do sistema supervisório no atual contexto tecnológico. Revista InTech 132, 6-18. Recuperado de https://www.aquarius.com.br/wp-content /uploads/2018/05/InTech132_artigo.pdf

Pleasant, B. (2023). The New Crestron: Enterprise and UC Platforms for the Modern Workplace. Crestron. Recuparado de https://www.crestron.com/getmedia/c6af4f29-fc5b-4c98-b191-33208780f142/wm_evolution_of_crestron_whitepaper

Sasaki, Y. & Yokotani, T. (2019). Performance evaluation of MQTT as a communication protocol for IoT and prototyping. Advances in Technology Innovation, 4(1), 21-29.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Brazilian Journal of Production Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Atribuição-NãoComercial-CompartilhaIgual

CC BY-NC-SA

This license lets others remix, adapt, and build upon your work non-commercially, as long as they credit you and license their new creations under the identical terms.