Maintenance management analysis of welding equipments in an agricultural machinery factory

DOI:

https://doi.org/10.47456/bjpe.v9i3.40839Keywords:

Maintenance, benchmarking, indicatorsAbstract

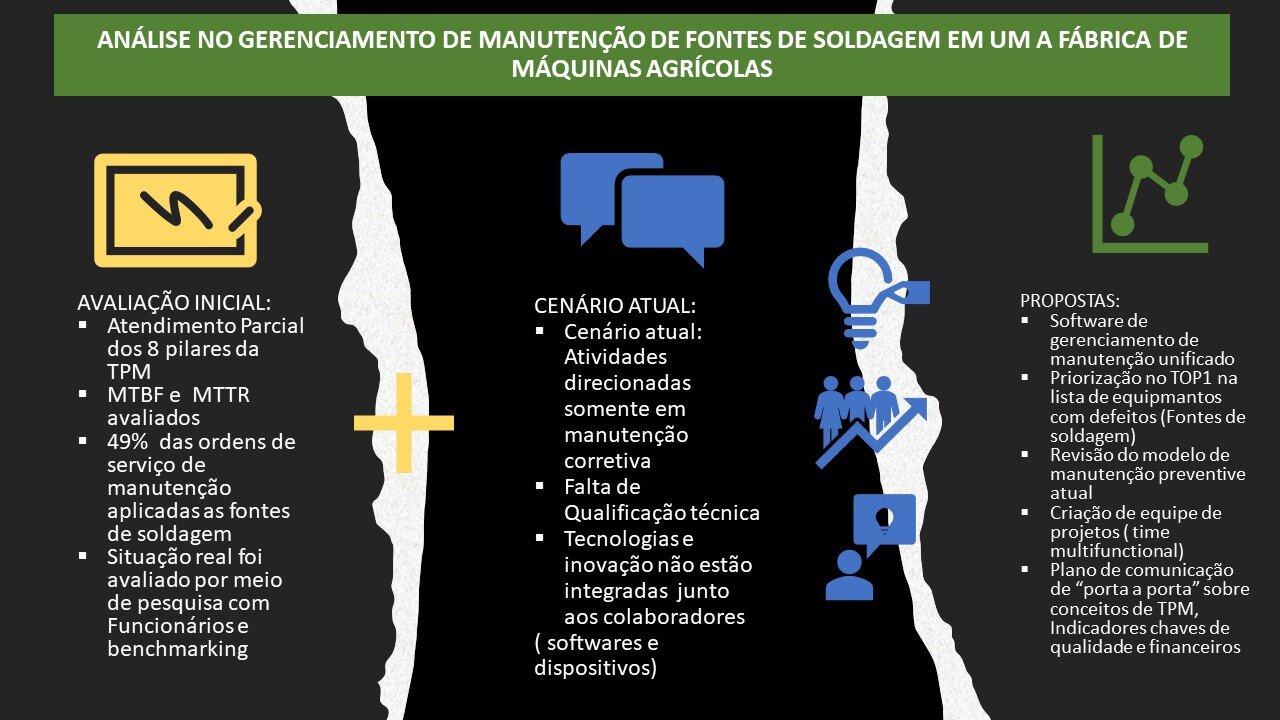

Maintenance management impacts several sectors of an organization, especially production. In factories where the welding process takes place, good maintenance management is important so that the equipment has the proper performance and does not negatively affect production. Given this context, the present work was developed with the aim of analyzing the maintenance process of the welding sector of an agricultural equipment factory to generate proposals for improvements. To this end, a participant research was developed, in which interviews were conducted with several employees of the organization who are involved in the maintenance and welding process. Data were collected through the organization's database and an internal benchmarking was carried out. As a result, it was observed that the TPM (total productive maintenance) is not developed consistently in the analyzed sector and possible improvements were identified. Therefore, it is concluded that the analysis of total productive maintenance provides the identification of improvements for the organization

Downloads

References

Associação brasileira de normas técnicas. (1994). NBR 5462: Confiabilidade e mantenabilidade. São Paulo, p. 37.

Bhutta, K. S. & Huq, F. (1999) Benchmarking - best practices: an integrated approach. Benchmarking: An International Journal, 6(3). 254-268. # MCB University. Press, 1463-5771. https://doi.org/10.1108/14635779910289261 DOI: https://doi.org/10.1108/14635779910289261

Chikwendu, O. C., Chima, A. S., & Edith, M.C. (2020) The optimization of overall equipment effectiveness factors in a pharmaceutical company. Heliyon, 6, 03796. https://doi.org/10.1016/j.heliyon.2020.e03796 DOI: https://doi.org/10.1016/j.heliyon.2020.e03796

Demmon, S., Bhargava, S., Ciolek, D., Halley, J., Jaya, N., Joubert, M. K., Koepf, E., Smithg, P., Trexler-Schmidt, M., & Tsa, P. (2020) A cross-industry forum on benchmarking critical quality attribute identification and linkage to process characterization studies. Biologicals, 67, 9-20. https://doi.org/10.1016/j.biologicals.2020.06.008 DOI: https://doi.org/10.1016/j.biologicals.2020.06.008

Franciosi, C, Voisin, A, Miranda, S., Riemma, S., & Iung, B. (2020). Measuring maintenance impacts on sustainability of manufacturing industries: from a systematic literature review to a framework proposal. Journal of Cleaner Production. 260 (121065). https://doi.org/10.1016/j.jclepro.2020.121065 DOI: https://doi.org/10.1016/j.jclepro.2020.121065

Gestão da manutenção: o mercado, as oportunidades e os desafios. ENGETELES, 2018, Brasília. Recuperado de https://engeteles.com.br/gestao-da-manutencao-o-mercado

Gil, A. C. (2008). Métodos e Técnicas de Pesquisa Social (6 ed.). São Paulo: Atlas.

Horenbeek, A. V. & Pintelon, L. (2014). Development of a maintenance performance measurement framework using the analytic network process (ANP) for maintenance performance indicator selection. Omega, 42, 33-46. https://doi.org/10.1016/j.omega.2013.02.006 DOI: https://doi.org/10.1016/j.omega.2013.02.006

Kardec, A. & Nascif, J. (2012) Manutenção: Função Estratégica. (4.ed). Rio de Janeiro: Qualitymark Editora.

Kumar, U., Galar, D., Aditya, P., & Stenstro¨m, C. (2013) Maintenance performance metrics: a state-of-the-art review. Journal of Quality in Maintenance Engineering, 19, 233-277. https://doi.org/10.1108/JQME-05-2013-0029 DOI: https://doi.org/10.1108/JQME-05-2013-0029

Lafraia, J. R. B (2001). Manual de confiabilidade, mantenabilidade e disponibilidade. (374 p) Rio de Janeiro: Qualitymark.

Liu, Q, Dong, M., Chen, F. F., Liu, W., & Ye, C. (2020). Multi-objective imperfect maintenance optimization for production system with an intermediate buffer. Journal of Manufacturing Systems, 56, 452-462. https://doi.org/10.1016/j.jmsy.2020.07.002 DOI: https://doi.org/10.1016/j.jmsy.2020.07.002

Manutenção de equipamentos de solda. Sonic System, Itupeva, SP. Recuperado de https://www.sonicsystem.com.br/manutencaoequipamentos-solda

Martins, P. & L, F. (1999). Administração da produção. São Paulo: Saraiva.

Mobley, R. K., Higgins, L. R., & Wikoff, D. J. (2008) Maintenance Engineering Handbook. 7.ed. New York: McGraw Hill.

Prodanov, C. C. & Freitas, E. C. (2013) Metodologia do Trabalho Científico: Métodos e Técnicas da Pesquisa e do Trabalho Acadêmico. 2.ed. Novo Hamburgo: Editora Feevale

Shin, W, Han, J., & Rhee, W. (2021) AI-assistance for predictive maintenance of renewable energy systems. Energy, 221, 119775. https://doi.org/10.1016/j.energy.2021.119775 DOI: https://doi.org/10.1016/j.energy.2021.119775

Singh, R., Gohil, A. M., Shah, D. B., & Desai, S. (2013) Total Productive Maintenance (TPM) Implementation in a Machine Shop: A Case Study. Procedia Engineering, 51, 592–599. https://doi.org/10.1016/j.proeng.2013.01.084 DOI: https://doi.org/10.1016/j.proeng.2013.01.084

The Welding Institute. TWI, Cambridge, Inglaterra. Recuperado de https://www.twi-global.com/who-we-are

Um quarto das empresas não possuem um setor de Planejamento e Controle de Manutenção (PCM). (2020). Revista Manutenção: Gestão, Estratégia e Inovação. 07 de set. de 2020. Recuperado de https://www.revistamanutencao.com.br/noticias/manutencao/um-quarto-das-empresas-nao-possuem-um-setor-de-planejamento-e-controle-de-manutencao-pcm.html

Van Harten, W. H, Van Bokhorst, L., & Van Luenen, H. G. A. M. (2010) Benchmarking biology research organizations using a new, dedicated tool. Molecular Oncology, 4, 12-18. https://doi.org/10.1016/j.molonc.2009.09.002 DOI: https://doi.org/10.1016/j.molonc.2009.09.002

Weber, A. & Thomas, R. (2005). Key performance indicators: measuring and managing the maintenance function. Ivara Corporation, Canadá. Recuperado de https://www.plant-maintenance.com/articles/KPIs.pdf

Wind, A. & Van Harten, W. H. (2017) Benchmarking specialty hospitals, a scoping review on theory and practice. BMC Health Services Research, 17:245. https://doi.org/10.1186/s12913-017-2154-y DOI: https://doi.org/10.1186/s12913-017-2154-y

Yin, R. K. (1994). Pesquisa Estudo de Caso - Desenho e Métodos (2 ed.). Porto Alegre: Bookman.

Zonta, T., Costa, C. A., Righ, R. R., Lima, M. J., Trindade, E. S., da., & Li, G. P. (2020) Predictive maintenance in the Industry 4.0: A systematic literature review. Computers & Industrial Engineering, 150, 106889. https://doi.org/10.1016/j.cie.2020.106889 DOI: https://doi.org/10.1016/j.cie.2020.106889

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Brazilian Journal of Production Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

All works published in the Brazilian Journal of Production Engineering (BJPE) are licensed under Creative Commons Attribution 4.0 International (CC BY 4.0).

This means that:

Anyone can copy, distribute, display, adapt, remix, and even commercially use the content published in the journal;

Provided that due credit is given to the authors and to BJPE as the original source;

No additional permission is required for reuse, as long as the license terms are respected.

This policy complies with the principles of open access, promoting the broad dissemination of scientific knowledge.

2.png)