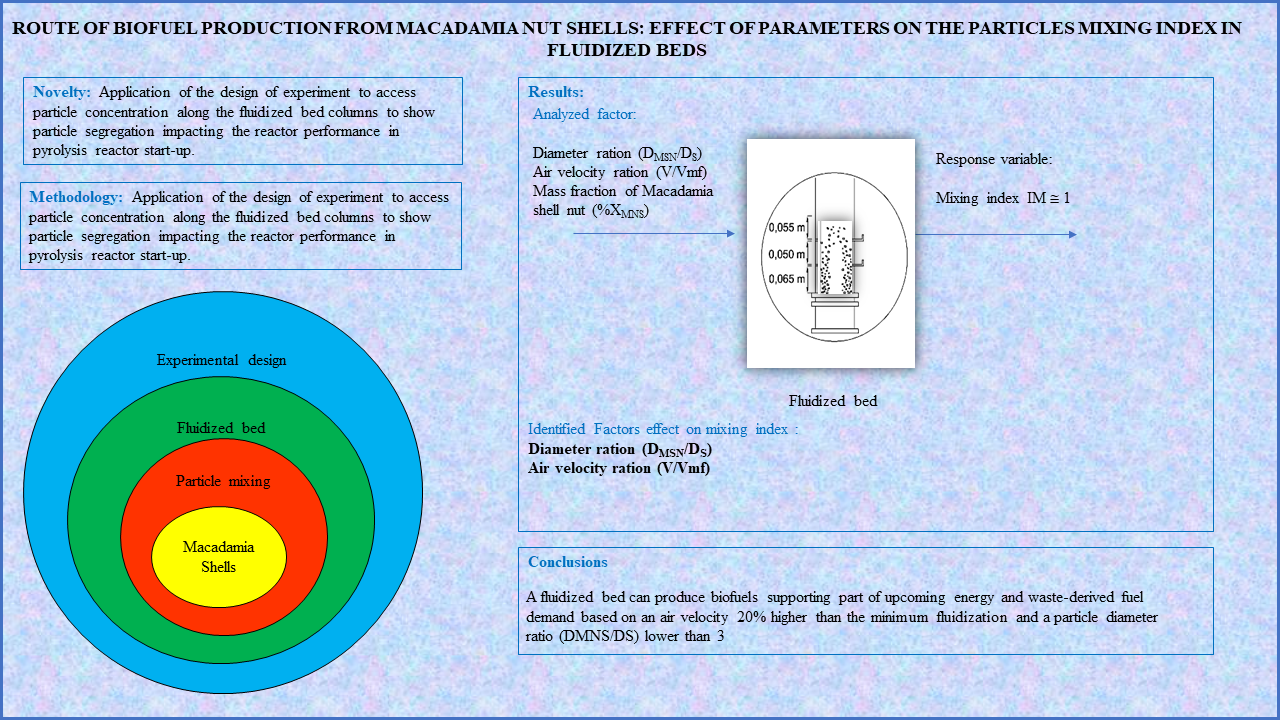

Route of biofuel production from macadamia nut shells: effect of parameters on the particles mixing index in fluidized beds

DOI:

https://doi.org/10.47456/bjpe.v9i1.40123Palavras-chave:

Biomassa, Fluidodinâmica, Energia, Segregação, SustentabilidadeResumo

Pyrolysis of macadamia nut shells (MNS) in a fluidized bed reactor has excellent potential to produce bio-oil. High heat transfer rates and uniform temperature in the fluidized bed can be achieved due to effective gas-solid contact in the reactor. However, binary mixtures can lead to the segregation of particles, which negatively affects heat and mass transfer in such a reactor. Therefore, a 2³ statistical experimental design was used to assess the effects of parameters (i.e., air velocity, particle diameter ratio, and mass fraction of MNS) on the mixing index of the bed of MNS and sand. Among the analyzed factors, only DMNS/DS and V/VMF influenced the mixing index (Im) within a confidence interval of 95%. Based on statistical data analysis, an air velocity 20% above the minimum fluidization and particle diameter ratio (DMNS/DS) smaller than 3 results in uniform particle mixing in the bed (i.e., reaching ideal mixing index values). Moreover, the experimental results indicate that fluidized be used for biofuel production from Macadamia nut Shells.

Downloads

Referências

Artetxe, M., Lopez, G., Amutio, M., Elordi, G., Olazar, M., & Bilbao, J. (2010). Operating Conditions for the Pyrolysis of Poly-(ethylene terephthalate) in a Conical Spouted-Bed Reactor. Industrial & Engineering Chemistry Research, 49(5), 2064–2069. https://doi.org/10.1021/ie900557c

Bacelos, M. S., & Freire, J. T. (2006). Stability of spouting regimes in conical spouted beds with inert particle mixtures. Industrial and Engineering Chemistry Research, 45(2). https://doi.org/10.1021/ie050633s

Barcelos, K. M., Almeida, P. S., Araujo, M. S., Xavier, T. P., Santos, K. G., Bacelos, M. S., & Lira, T. S. (2020). Particle segregation in spouted bed pyrolysis reactor: Sand-coconut shell and sand-cocoa shell mixtures. Biomass and Bioenergy, 138, 105592. https://doi.org/10.1016/j.biombioe.2020.105592

Daleffe, R. V., & Freire, J. T. (2004). Analysis of the fluid-dynamic behavior of fluidized and vibrofluidized bed containing glycerol. Brazilian Journal of Chemical Engineering, 21(1), 35–46. https://doi.org/10.1590/S0104-66322004000100005

Freitas, T. M., Arrieche, L. S., Ribeiro, D. C., Gidaspow, D., & Bacelos, M. S. (2017). CFD analysis of fluidized beds using wastes from post-consumer carton packaging. Chemical Engineering and Processing: Process Intensification, 111, 89–100. https://doi.org/10.1016/j.cep.2016.12.002

Gong, Y., & Pegg, R. B. (2015). Tree nut oils: Properties and processing for use in food. Specialty Oils and Fats in Food and Nutrition: Properties, Processing and Applications, 65–86. https://doi.org/10.1016/B978-1-78242-376-8.00003-X

Hasan, M. M., Rasul, M. G., Jahirul, M. I., & Khan, M. M. K. (2022). Modeling and process simulation of waste macadamia nutshell pyrolysis using Aspen Plus software. Energy Reports, 8, 429–437. https://doi.org/10.1016/J.EGYR.2022.10.323

Hidaka, N., Onitani, M., Matsumoto, T., & Shigeharu, M. (1995). Inverted segregation of binary particles in gas-liquid-solid fluidized bed. Powder Technology, 84, 157–163.

Iannello, S., Bond, Z., Sebastiani, A., Errigo, M., & Materazzi, M. (2023). Axial segregation behaviour of a reacting biomass particle in fluidized bed reactors: experimental results and model validation. Fuel, 338, 127234. https://doi.org/10.1016/J.FUEL.2022.127234

Ji, X., Bie, R., Chen, P., & Gu, W. (2016). Reed Black Liquor Combustion in Fluidized Bed for Direct Causticization with Limestone as Bed Material. Energy and Fuels, 30(7), 5791–5798. https://doi.org/10.1021/ACS.ENERGYFUELS.6B00847

José, M. J. S., Olazar, M., Peñas, F. J., & Bilbao, J. (1994a). Segregation in Conical Spouted Beds with Binary and Ternary Mixtures of Equidensity Spherical Particles. 1838–1844. https://doi.org/10.1021/ie00031a025

José, M. J. S., Olazar, M., Peñas, F. J., & Bilbao, J. (1994b). Segregation in Conical Spouted Beds with Binary and Ternary Mixtures of Equidensity Spherical Particles. 1838–1844. https://doi.org/10.1021/ie00031a025

Lee, J., Kim, S., You, S., & Park, Y. K. (2023). Bioenergy generation from thermochemical conversion of lignocellulosic biomass-based integrated renewable energy systems. Renewable and Sustainable Energy Reviews, 178, 113240. https://doi.org/10.1016/J.RSER.2023.113240

Lopez, G., Artetxe, M., Amutio, M., Bilbao, J., & Olazar, M. (2017). Thermochemical routes for the valorization of waste polyolefinic plastics to produce fuels and chemicals. A review. In Renewable and Sustainable Energy Reviews, 73, 346–368. Elsevier Ltd. https://doi.org/10.1016/j.rser.2017.01.142

López, G., Olazar, M., Aguado, R., & Bilbao, J. (2010). Continuous pyrolysis of waste tyres in a conical spouted bed reactor. Fuel, 89(8), 1946-1952. https://doi.org/10.1016/J.FUEL.2010.03.029

Mantegazini, D. Z., Neves, F. L., Xavier, T. P., & Bacelos, M. S. (2021). Review on advanced technologies for aluminum recovery from carton packages waste using pyrolysis. Brazilian Journal of Production Engineering-BJPE, 7(1), 117–129. https://doi.org/10.47456/bjpe.v7i1.34583

Marques, I. I. D. R., & Bacelos, M. S. (2013). Analysis of conical spouted bed fluid dynamics using carton mixtures. Chemical Engineering and Processing: Process Intensification, 70, 37–47. https://doi.org/10.1016/j.cep.2013.05.009

Martinez Castilla, G., Larsson, A., Lundberg, L., Johnsson, F., & Pallarès, D. (2020). A novel experimental method for determining lateral mixing of solids in fluidized beds – Quantification of the splash-zone contribution. Powder Technology, 370, 96–103. https://doi.org/10.1016/J.POWTEC.2020.05.036

Massaro Sousa, L., & Ferreira, M. C. (2020). On the performance of a spouted bed type device for feeding spent coffee grounds to a circulating fluidized bed reactor. Chemical Engineering Research and Design, 160, 31–38. https://doi.org/10.1016/J.CHERD.2020.05.002

Melo, J. L. Z., Bacelos, M. S., Pereira, F. A. R., Lira, T. S., & Gidaspow, D. (2016). CFD modeling of conical spouted beds for processing LDPE/Al composite. Chemical Engineering and Processing: Process Intensification, 108, 93–108. https://doi.org/10.1016/j.cep.2016.07.011

Norouzi, H. R., Mostoufi, N., & Sotudeh-Gharebagh, R. (2012). Effect of fines on segregation of binary mixtures in gas-solid fluidized beds. Powder Technology, 225, 7–20. https://doi.org/10.1016/j.powtec.2012.03.025

Nunes, C. A., Freitas, M. P., Pinheiro, A. C. M., & Bastos, S. C. (2012). Chemoface: a novel free user-friendly interface for chemometrics. Journal of the Brazilian Chemical Society, 23(11), 2003–2010. https://doi.org/10.1590/S0103-50532012005000073

Parikh, J., Channiwala, S. A., & Ghosal, G. K. (2005). A correlation for calculating HHV from proximate analysis of solid fuels. Fuel, 84(5), 487–494. https://doi.org/10.1016/J.FUEL.2004.10.010

Saidi, M., Basirat Tabrizi, H., Chaichi, S., & Dehghani, M. (2014). Pulsating flow effect on the segregation of binary particles in a gas-solid fluidized bed. Powder Technology, 264, 570–576. https://doi.org/10.1016/j.powtec.2014.06.003

Samoraj, M., Izydorczyk, G., Krawiec, P., Moustakas, K., & Chojnacka, K. (2022). Biomass-based micronutrient fertilizers and biofortification of raspberries fruits. Environmental Research, 215, 114304. https://doi.org/10.1016/J.ENVRES.2022.114304

Selvatici, A. C., Mantegazini, D. Z., & Bacelos, M. S. (2021). Produção de combustível a partir de resíduos de embalagens tetra pak em leito fluidizado: identificação de fatores que afetam a mistura de partículas de areia e compósito PEBD/AL. Brazilian Journal of Production Engineering, 7(5), 133–144. https://doi.org/10.47456/BJPE.V7I5.36926

Soria-Verdugo, A., Cano-Pleite, E., Passalacqua, A., & Fox, R. O. (2023a). Effect of particle shape on biomass pyrolysis in a bubbling fluidized bed. Fuel, 339, 127365. https://doi.org/10.1016/J.FUEL.2022.127365

Soria-Verdugo, A., Cano-Pleite, E., Passalacqua, A., & Fox, R. O. (2023b). Effect of particle shape on biomass pyrolysis in a bubbling fluidized bed. Fuel, 339. https://doi.org/10.1016/j.fuel.2022.127365

Soria-Verdugo, A., Rubio-Rubio, M., Goos, E., & Riedel, U. (2020). On the characteristic heating and pyrolysis time of thermally small biomass particles in a bubbling fluidized bed reactor. Renewable Energy, 160, 312–322. https://doi.org/10.1016/j.renene.2020.07.008

Strezov, V., Patterson, M., Zymla, V., Fisher, K., Evans, T. J., & Nelson, P. F. (2007). Fundamental aspects of biomass carbonisation. Journal of Analytical and Applied Pyrolysis, 79(1–2), 91–100. https://doi.org/10.1016/J.JAAP.2006.10.014

Tchoffor, P. A., Davidsson, K. O., & Thunman, H. (2015). Production of Activated Carbon within the Dual Fluidized Bed Gasification Process. Industrial and Engineering Chemistry Research, 54(15), 3761–3766. https://doi.org/10.1021/IE504291C

Tran, Q. K., Han, S., Ly, H. V., Kim, S. S., & Kim, J. (2020). Hydrodeoxygenation of a bio-oil model compound derived from woody biomass using spray-pyrolysis-derived spherical γ-Al2O3-SiO2 catalysts. Journal of Industrial and Engineering Chemistry, 92, 243–251. https://doi.org/10.1016/J.JIEC.2020.09.012

Wang, S., Hu, C., Luo, K., Yu, J., & Fan, J. (2022). Multi-scale numerical simulation of fluidized beds: Model applicability assessment. Particuology. https://doi.org/10.1016/J.PARTIC.2022.11.011

Wang, S., & Shen, Y. (2021). Particle-scale study of heat and mass transfer in a bubbling fluidised bed. Chemical Engineering Science, 240, 116655. https://doi.org/10.1016/J.CES.2021.116655

Xavier, T. P., Libardi, B. P., Lira, T. S., & Barrozo, M. A. S. (2016). Fluid dynamic analysis for pyrolysis of macadamia shell in a conical spouted bed. Powder Technology, 299, 210–216. https://doi.org/10.1016/J.POWTEC.2016.05.034

Yang, C., Kwon, H., Bang, B., Jeong, S., & Lee, U. (2022). Role of biomass as low-carbon energy source in the era of net zero emissions. Fuel, 328, 125206. https://doi.org/10.1016/J.FUEL.2022.125206

Zhou, M., Wang, S., Luo, K., & Fan, J. (2022). Three-dimensional modeling study of the oxy-fuel co-firing of coal and biomass in a bubbling fluidized bed. Energy, 247, 123496. https://doi.org/10.1016/J.ENERGY.2022.123496

Downloads

Publicado

Edição

Seção

Licença

Copyright (c) 2023 Bárbara Mendonça, Diunay Mantegazini, Yuri Nariyoshi, Marcelo Silveira Bacelos (Autor)

Este trabalho está licenciado sob uma licença Creative Commons Attribution 4.0 International License.

Atribuição 4.0 internacional CC BY 4.0 Deed

Esta licença permite que outros remixem, adaptem e desenvolvam seu trabalho não comercialmente, contanto que eles creditem a você e licenciem suas novas criações sob os mesmos termos.

2.png)