Iron ore milling and the comminution process: a bibliometric analysis

DOI:

https://doi.org/10.47456/bjpe.v7i5.36903Keywords:

Iron Ore, Milling, Comminution , Web of ScienceAbstract

The context of the growing global scarcity of high iron content ores is a stimulus for the fragmentation equipment for less concentrated fines to be increasingly used and their studies revisited. This study had as its premise the investigation of scientific production regarding the process of comminution of iron ore through grinding. Methodologically, a bibliometric analysis was carried out through the selection of articles in the collection available free of charge to compose the portfolio, in order to map the pertinent literature, describe which means the most relevant studies on the subject are inserted, and so by individual listings proceed their qualitative analysis. The results address the importance of testing solutions and improving studies in this area, as it has great potential and the need for technical and operational improvements that enable an improvement in the specific cost of the product. Therefore, several authors highlight solutions for a more efficient processing of the fragmentation of this ore in the midst of the current economic challenge.

Downloads

References

Aldrich C. (2013). Consumption od steel grinding media in mills – a review. Minerals Engineering.

Batchelor, A. R., Buttress, A. J., Jones, D. A., Katrib, J., Way, D., Chenje, T., Stoll, D., Dodds, C., & Kingman, S. W. (2017). Towards large scale microwave treatment of ores: Part 2 – Metallurgical testing. Minerals Engineering.

Bond, F. C. (1952). The third theory of comminution. AIME Mining Engineering.

Cao, J., Liu, L., Han, Y., & Feng, A. (2019). Comminution behavior and mineral liberation characteristics of low-grade hematite ore in high pressure grinding roll. Physicochemical Problems of Mineral Processing.

Cassola, M. S., Moraes, S. L., & Albertin, E. (2006). Desgaste na mineração: o caso dos corpos moedores. Revista Escola de Minas.

Deniz, V. (2013). Comparisons of Dry Grinding Kinetics of Lignite, Bituminous Coal, and Petroleum Coke. Energy Sources.

Franck, A. G. S., Coronel, D. A., Silva, M. L., & Silva, R. A. (2015). Competitividade das exportações australianas e brasileiras de minério de ferro para a China (1999-2014). NECAT.

Fu, H., Wang, M., & Ho, Y. (2013). Mapping of drinking water research: A bibliometric analysis of research output during 1992–2011. Science of the Total Environment.

Goldbarg, M. C., & Luna H. P. L. (2000). Otimização Combinatória e Programação Linear: modelos e algoritmos. São Paulo.

Hanumanthappha, H., Vardsha, V., Mandela, G. R., Kaza, M., Sah, R., & Shanmugam, B. K. (2020). Estimation of Grinding Time for Desired Particle Size Distribution and for Hematite Liberation Based on Ore Retention Time in the Mill. Mining, Metallurgy & Exploration

Hasankhoei, A. R., Maleki-Moghaddam, M., Haji-Zadeh, A., Barzgar, M. E., & Banisi, S. (2019). On dry SAG mills end liners: Physical modeling, DEM-based characterization and industrial outcomes of a new design. Minerals Engineering.

Hukki, R.T. (1962). Proposal for a solomonic settlement between the theories of von Rittinger, Kick, and Bond. AIME Mining Engineering.

Jankovic, A., Dundar, H., & Mehta, R. (2010). Relationships between comminution energy and product size for a magnetite ore. The Southern African Institute of Mining and Metallurgy.

Jeswiet, J., & Szekeres, A. (2016). Energy Consumption in Mining Comminution. Procedia CIRP. CIRP Conference on Life Cycle Engineering, Kingston, Ontario, Canada, 23.

Kallembackk, R. D. C. (2012). Investigação da moagem de misturas binárias em moinhos de bolas (Dissertação de mestrado). Universidade Federal do Rio de Janeiro. Rio de Janeiro, RJ, Brasil.

Kick, F. (1885). Das Gesetz der proporionalen Widerstande und seine anwendung felix. Leipzig: Kessinger Publishing.

Koseoglu, M. A., Rahimi, R., Okumus, F., & Liu, J. (2016). Bibliometric studies in tourism. Annals of Tourism Research.

Lacerda, R. T. O., Enssline, L., & Enssline, S. R. (2012). Uma análise bibliométrica da literatura sobre estratégia e avaliação de desempenho. Gestão & Produção.

Li, T., Yin, Z., & Wu, G. (2021). Study on heat transfer behavior and thermal breakage characteristic of the charge in ball mills. Advances in Mechanical Engineering.

Little, L., Mainza, A. N., Becker, M., & Wiese, J. G. (2016). Using mineralogical and particle shape analysis to investigate enhanced mineral liberation through phase boundary fracture. Powder Technology.

Parapari, P. S., Parian, M., & Rosenkranzr, J. (2020). Breakage process of mineral processing comminution machines – An approach to liberation. Minerals and Metallurgical Engineering.

Peltoniemi, M., Kallio, R., Tanhua, A., Luukkanen, S., & Peramaki, P. (2020). Mineralogical and surface chemical characterization of flotation feed and products after wet and dry grinding. Minerals Engineering.

Popescu, G. H., Nica, E., Nicolaescu, E., & Lazaroiu, G. (2016). China’s steel industry as a driving force for economic growth and international competitiveness. METABK.

Powell, M., Condori, P., Smit, I., & Valery, W. Jr. (2006). The Value of Rigorous Surveys – The Los Bronces Experience. SAG2006 – Operations and Maintenance. International Conference on Autogenous and Semiautogenous Grinding Technology, Vancouver, Canada.

Queiroz, A. M., Fulgencio, R. A. M., Corrêa, G. H., El Hajj, T., M., & Gomes, W. L. (2017). Ensaios de Moagem e WI para Minério de Ferro. Encontro Nacional de Tratamento de Minérios e Metalurgia Extrativa, Belém, PA, Brasil, 27.

Reichert, M., Gerold, C., Fredriksson, A., Adolfssona, G., & Lieberwirth H. (2015). Research of iron ore grinding in a vertical-roller-mill. Minerals Engineering.

Rittinger, P. R. (1867). Lehrbuch der Aufbereitungskunde. Ernst e Korn, Berlim, Reconhecimento Alemanha.

Rodrigues, A. F. d. V., Delboni, H. Jr., Powell, M. S., & Tavares, L. M. T. (2021). Comparing strategies for grinding itabirite iron ores in autogenous and semi-autogenous pilot-scale mills. Minerals Engineering.

Roveri, E., & Chaves, A. P. (2011). Mecanismos de desgaste de corpos moedores em moinhos de bolas. Tecnologia em metalurgia, materiais e mineração.

Ruiz, M. A., Greco, O. T., & Braile, D. M. (2009). Fator de impacto: importância e influência no meio editorial, acadêmico e científico. Revista Brasileira de Cirurgia Cardiovascular.

Silva, A. C. R. (2010). Metodologia da pesquisa aplicada à contabilidade: orientações de estudos, projetos, artigos, relatórios, monografias, dissertações, teses. (3ª ed.). São Paulo: Atlas.

Thomazini, A. D., Trés, E. P., Macedo, F. A. D., Athayde, M., Bueno, G., Fernandes, R. B., & Nunes, R. A. P. (2020). Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit. Mining, Metallurgy & Exploration.

United Nations Conference on Trade and Development (UNCTAD, 2016). The Iron Ore Market.

United States Geological Survey (USGS, 2017). Mineral commodity summaries.

Walker, W. H., Lewis, W. K., McAdams, W. H., & Gilliland, E. R. (1937). Principles of Chemical Engineering. McGraw-Hill, NY, EUA.

Wang, Y., & Forssberg, E. (2007). Enhancement of energy efficiency for mechanical production of fine and ultra-fine particles in comminution. China Particuology.

Wills, B. A. & Napier-Munn, T. (2006). Mineral Processing Technology - An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery. (7ª ed.). Austrália: Butterworth-Heinemann.

Downloads

Published

How to Cite

Issue

Section

License

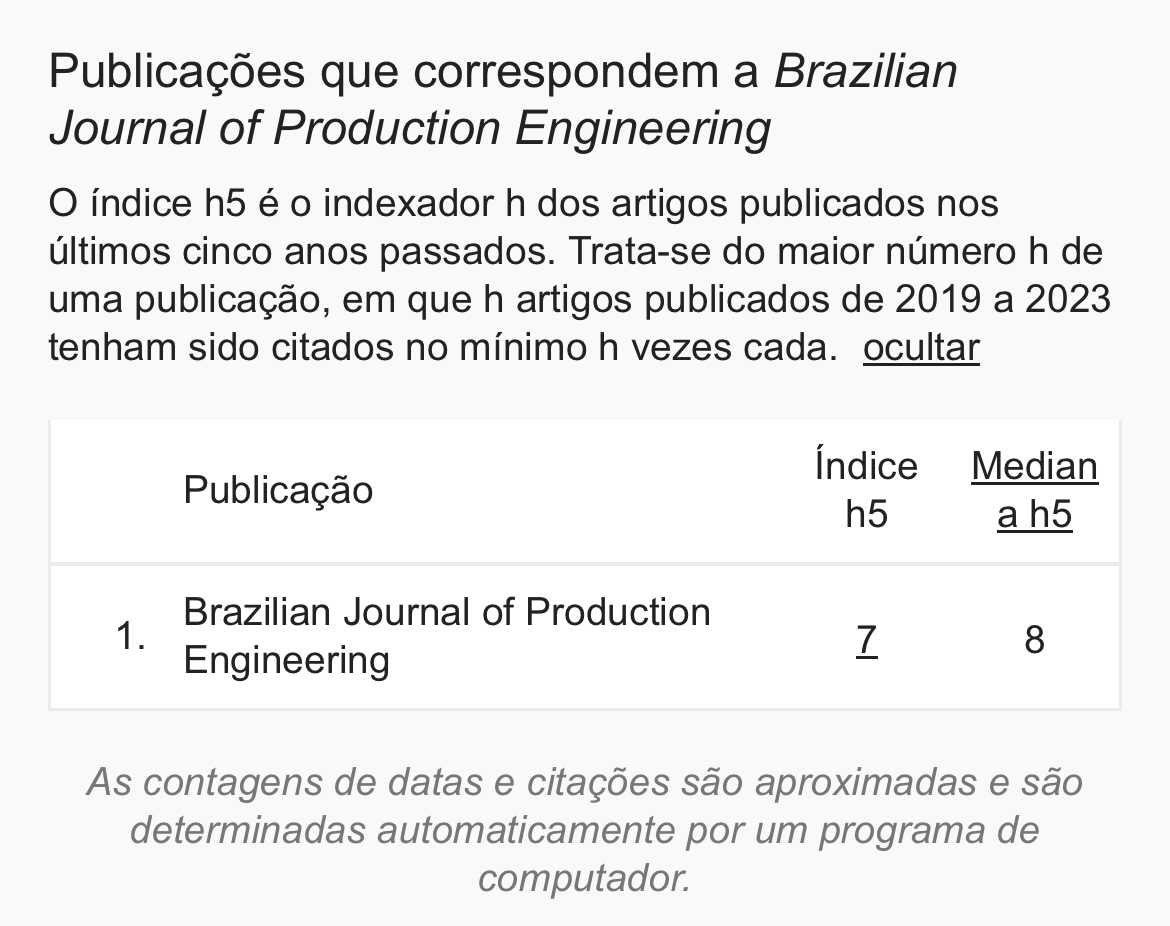

Copyright (c) 2021 Brazilian Journal of Production Engineering - BJPE

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.